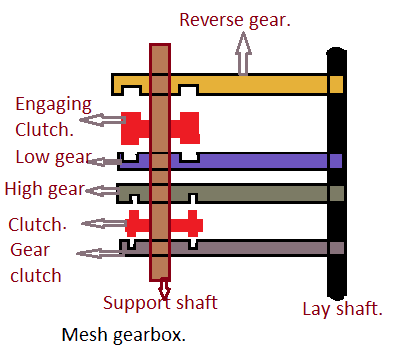

Before the introduction of the synchromesh gearbox in 1928 by General Motors, the Constant Mesh Box was used in motorbikes also. The main objective is to connect all mechanical engineering people all over the world. For the smooth engagement of dog clutches, it is required that the speed of the main shaft gears and the dog clutch must be equal. The dog clutch (D2) slides towards its right and engages with the 2nd gear on the main shaft. The line diagram of the Constant Mesh Gearbox is shown below. Synchronizer gearbox will be no slip in the case of the synchromesh gearbox. Note: The power will be transmitted after the engagement of Dogclutch which was mentioned in the figure. While in slip takes place in the constant mesh gearbox. ADVANTAGESGear changing is very much simplifiedLess wear in gearsQuietDISADVANTAGES:Design is very much complexInitial cost is highQuick change of gears occurs due to noise of crashing. The power is transmitted from the Clutch shaft to Gear A mounted on the layshaft. What is the difference between constant mesh and synchromesh gearbox? The automatic transmission also referred to as full auto gearbox is a completely automated gearbox that self-changes gear ratios as the ve Galvanizing is an iron or steel sheet coating process with a thin zinc coat to avoid rusting. Skill is required for it. The layshaft is an intermediate shaft between the clutch shaft and the Main shaft which provides meshing of fixed gears to the movable gears to provide the output appropriately. Required fields are marked *, Sliding Mesh Gearbox: Components, Working, Advantages, Disadvantages, and Applications [PDF] In automobiles, Sliding Mesh Gearbox is one of the transmission systems which is of the oldest type. Copyright 2019 www.mechanicalfunda.com The content is copyrighted and may not be reproduced All right reserved, MECHANICALFUNDA A Vision To Clear Solutions And Bringing Your Ideas And Innovations To Life, 2016-2021 mechanicalfunda.com The content is copyrighted and may not be reproduced. What is the main difference between sliding mesh gearbox and constant mesh gearbox? If you continue to use this site we will assume that you are happy with it. We use cookies to ensure that we give you the best experience on our website. The Mechanical Efficiency was very low in the case of Sliding Mesh Gearbox. If you continue to use this site we will assume that you are happy with it. There are three types of shafts in the case of Sliding Mesh Gearbox. All the gear do not revolve at the same speeds & when we have to engage two gears running at different speeds by shift lever there will be some sound due to clashes of gears and very hard to engage and disengage the gears. The teeth of dog clutch is less wear and tear in engagement and disengagement of gears. Disadvantages: It is less efficient than the others due to higher mesh teeth. It helps the turning of drive around 90 and to drive driving wheels at different speed. Instead of using dog clutches here and also synchronizers are used. The synchromesh gearbox is used to engage also to disengage gear but in constant mesh, gearbox used to engage and disengage gears. To simplify the operations of changing gears without the occurrence of clashes and their consequent damage, a synchromesh gearbox is used in different type of motor vehicles.Helical gears are usedIt has synchromesh unit instead of dog clutch.The synchronizer helps to synchronize the speeds of two gears to be engaged. Types of Gear Box Sliding Mesh type gear box Constant Mesh type gear box Synchro Mesh type gear box Planetary type gear box. Explanation: As the gears are always in mesh in the constant-mesh gearbox, therefore there is no need for using the spur gears and the helical gears are used as those are quite in use. MECHANICALFUNDA | ONLINE MECHANICAL ENGINEERING | KNOWLEDGE | RESEARCH | INFORMATION |, Difference between Capstan and Turret Lathe, Difference between Capstan Turret and Engine Lathe, Difference between Open and Closed Die Forging, Difference between Hot Rolling and Cold Rolling, Difference between Understeer and Oversteer, Difference between Drum Brake and Disc Brake, Difference between Mechanical and Hydraulic Disc Brake, Difference between an Automatic and Manual Transmission, Difference between Spontaneous and Stimulated Emission, Difference between Static and Dynamic Balancing, Difference between Brayton and Rankine cycle, Difference between battery ignition system and magneto ignition system, Difference between conventional and non-conventional machining, Difference between the heat exchanger and condenser, Difference between laser and electron beam welding, Difference between annealing and normalizing, Difference between nuclear fission and nuclear fusion, Difference between electrochemical and galvanic series, Difference between galvanizing and tinning, Difference between addition and condensation polymerization, Difference between physical and chemical adsorption, Difference between adsorption and absorption, Difference between herringbone and double helical gears, Difference between thermoplastic and thermosetting plastic, Difference between manufacturing and production, Difference between clamp coupling and muff coupling, Difference between kinematic viscosity and dynamic viscosity, Difference between viscosity and friction, Difference between the set screw and cap screw, Difference between the rigid and flexible coupling, Difference between malleability and ductility, Difference between resilience and toughness, Difference between elasticity and plasticity, Difference between carburettor and fuel injector, Difference between the spur gear and helical gear, Difference between kinematics and dynamics, Difference between carburizing and nitriding, Difference between front-wheel drive and rear-wheel drive, Difference between a dry clutch and wet clutch, Difference between V engine and inline engine, Difference between management and administration, Difference between welding and fabrication, Difference between the air filter and cabin filter, Difference between Watt and Proell Governor, Difference between an anodic and cathodic coating, Difference between galvanizing and electroplating, Closed die forging - Advantages and Disadvantages, Open die forging - Advantages and Disadvantages, Resistance welding - Advantages and Disadvantages, Carburizing - Advantages and Disadvantages, Roller burnishing - Advantages and Disadvantages, Electrochemical machining - Advantages and Disadvantages, Internal expanding brake - Advantages and Disadvantages, Stirling engine - Advantages and Disadvantages, Abrasive jet machining - Advantages and Disadvantages, Carburettor - Advantages and Disadvantages, Gaseous fuel - Advantages and Disadvantages, Magneto ignition system - Advantages and Disadvantages, Projection welding - Advantages and Disadvantages, Belt drive - Advantages and Disadvantages, V Belt drive - Advantages and Disadvantages, Electron beam welding - Advantages and Disadvantages, Laser beam welding - Advantages and Disadvantages, TIG welding - Advantages and Disadvantages, Friction welding - Advantages and Disadvantages, Liquid fuel - Advantages and Disadvantages, Solid fuel - Advantages and Disadvantages, Double helical gear - Advantages and Disadvantages, Clamp coupling - Advantages and Disadvantages, Woodruff key - Advantages and Disadvantages, Rigid flange coupling - Advantages and Disadvantages, Riveted joints - Advantages and Disadvantages, Shell mould casting - Advantages and Disadvantages, Investment casting - Advantages and Disadvantages, Permanent mould casting - Advantages and Disadvantages, Sand casting - Advantages and Disadvantages, Die casting - Advantages and Disadvantages, Electron beam machining - Advantages and Disadvantages, Hot rolling - Advantages and Disadvantages, Cold rolling - Advantages and Disadvantages, Polythene bag - Advantages and Disadvantages, Electro-chemical grinding - Advantages and Disadvantages, Chemical machining - Advantages and Disadvantages, Laser beam machining - Advantages and Disadvantages, Ultrasonic machining - Advantages and Disadvantages, Electric discharge machining - Advantages and Disadvantages, Automatic transmission system - Advantages and Disadvantages, Supercharger - Advantages and Disadvantages, HCCI engine - Advantages and Disadvantages, GDI engine - Advantages and Disadvantages, Free piston engine - Advantages and Disadvantages, Centrifugal casting - Advantages and Disadvantages, Disc brakes - Advantages and Disadvantages, Fuel injection system - Advantages and Disadvantages, Two-stroke engine - Advantages and Disadvantages, Front-wheel drive - Advantages and Disadvantages, Wankel engine - Advantages and Disadvantages, Electromagnetic clutch - Advantages and Disadvantages, Fluid clutch - Advantages and Disadvantages, Dual-clutch transmission - Advantages and Disadvantages, Automated manual transmission - Advantages and Disadvantages, Continuous variable transmission - Advantages and Disadvantages, Job shop production - Advantages and Disadvantages, Batch production - Advantages and Disadvantages, Mass production - Advantages and Disadvantages. Whereas dog clutches are used to engage and disengage gears. What is the main drawback of constant mesh gearbox? This lever is used by the driver to change the gear by employing a selective mechanism. The Advantages of Constant Mesh Gearbox are as follows. During engagement and disengagement, the wear of dog teeth is reduced because all the teeth of dog clutches are involved in the meshing when compared to the sliding gears where only 2 or 3 teeth were under the mesh. Which of the gears are used in constant mesh gearbox? The Torque acquired is smaller and the speed acquired is larger than the first gear and this can be obtained when the driver pulls the lever for the 2nd gear. There is no need for straight spur gears because the gears were always in mesh in the case of a constant mesh gearbox. In this gearbox, the sliding mesh was replaced with constantly meshed pairs of gears and the new shifting devices named dog clutches were introduced. The difference between Constant Mesh Gearbox and Synchromesh Gearbox is as follows. The hollow shaft contains the same amount of material all at the ends if hollow and a solid shaft are of the same weight whereas in the so CNC full form is Computer Numerical Control while VMC full form is Vertical Machining Center. So, in this way, double-declutching is taking place in the case of Constant Mesh Gearbox. Introduction of Transmission Systems:, Synchromesh Gearbox: Construction, Working Principle, Advantages, Disadvantages, and Applications [PDF] Synchromesh Gearbox is similar to the Constant Mesh Gearbox in which dog clutches in the Constant Mesh Gearbox are replaced by Synchromesh devices for smoother engagement of gears. 1. output shaft 2.Low and reverse sliding gear 3. The power is transmitted from the Clutch shaft to the clutch gear which is attached at the end of it.