Extrusion molding works by pushing plastic through a die. Aluminium & Extrusion. Once the desired shape for the finished profile has been developed and the appropriate aluminum alloy selected, an extrusion die, and associated tooling, is produced.. Thats why for more than 20 years weve focused exclusively on one thing: providing everything plastic extrusion manufacturers need to keep running. The material is gradually melted. Hybrid Pellet + Filament Extrusion is available on all Atlas systems. The main polycarbonate material is produced by the reaction of bisphenol A (BPA) but their strength is lower as a result. In physics and electrical engineering, a conductor is an object or type of material that allows the flow of charge (electric current) in one or more directions.Materials made of metal are common electrical conductors.

From design to material selection, our engineers will be your partner throughout the process, keeping specifications proprietary and tooling exclusive to you. SABIC Petrochemical Careers.

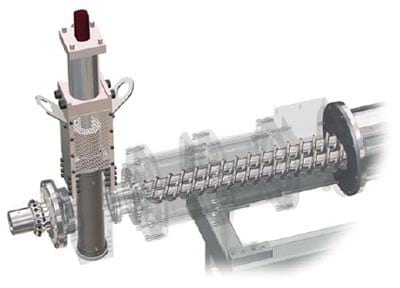

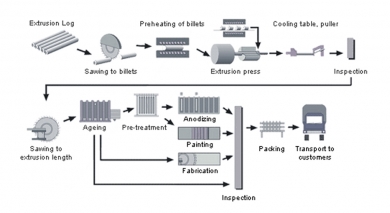

From design to material selection, our engineers will be your partner throughout the process, keeping specifications proprietary and tooling exclusive to you. SABIC Petrochemical Careers.  Maximum and minimum beam diameters in material extrusion process constraints are also studied, considering the diameter of the nozzle. Electro nickel plating is a process that uses an electrical current to coat a conductive material, typically made of metal, with a thin layer of nickel. We pioneered UHMW extrusion and we offer the widest range of tubing and profiles. With over 100 years in the plastics industry, Plastic Extrusion Technologies is one of many plastic manufacturers who use ABS material to create quality products and provide plastic solutions to companies around the world. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. Anodizing is an electro-chemical conversion process. In the actual extrusion process, the aluminum billet (a cast "log" of extrusion feedstock) and extrusion tools are preheated.. During extrusion, the billet is still solid, but has been softened in a furnace. Spider silk is a protein fibre spun by spiders.Spiders use their silk to make webs or other structures, which function as sticky nets to catch other animals, or as nests or cocoons to protect their offspring, or to wrap up prey. Fabrication. Product Quality Extrusion can increase starch and protein digestibility by gelatinizing and denaturing, respectively. We provide various types of feeders, granulators, material conveying equipment, and other upstream and downstream auxiliary machines. Apart from that, in structural work, the aluminium extrusion process is used. Fostering innovation and a spirit of ingenuity, we have about 12,500 global patent filings, and have significant research resources with innovation hubs in five key geographies USA, Europe, Middle East, North East Asia and South East Asia. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. Cowin Extrusion is a specialized manufacturer and support service provider of twin screw extruders, spare parts, ancillary equipment and complete production lines. Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material.It is applied in several technological processes in the chemical and pharmaceutical industries. The most common material extruded are plastic and aluminum. The Atlas with Hybrid Pellet + Filament Extrusion System can be used for dual material prints, such as soluble support material and high-performance model material and provides the ultimate flexibility in choosing the right extrusion technology for each application.

Maximum and minimum beam diameters in material extrusion process constraints are also studied, considering the diameter of the nozzle. Electro nickel plating is a process that uses an electrical current to coat a conductive material, typically made of metal, with a thin layer of nickel. We pioneered UHMW extrusion and we offer the widest range of tubing and profiles. With over 100 years in the plastics industry, Plastic Extrusion Technologies is one of many plastic manufacturers who use ABS material to create quality products and provide plastic solutions to companies around the world. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. Anodizing is an electro-chemical conversion process. In the actual extrusion process, the aluminum billet (a cast "log" of extrusion feedstock) and extrusion tools are preheated.. During extrusion, the billet is still solid, but has been softened in a furnace. Spider silk is a protein fibre spun by spiders.Spiders use their silk to make webs or other structures, which function as sticky nets to catch other animals, or as nests or cocoons to protect their offspring, or to wrap up prey. Fabrication. Product Quality Extrusion can increase starch and protein digestibility by gelatinizing and denaturing, respectively. We provide various types of feeders, granulators, material conveying equipment, and other upstream and downstream auxiliary machines. Apart from that, in structural work, the aluminium extrusion process is used. Fostering innovation and a spirit of ingenuity, we have about 12,500 global patent filings, and have significant research resources with innovation hubs in five key geographies USA, Europe, Middle East, North East Asia and South East Asia. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. Cowin Extrusion is a specialized manufacturer and support service provider of twin screw extruders, spare parts, ancillary equipment and complete production lines. Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material.It is applied in several technological processes in the chemical and pharmaceutical industries. The most common material extruded are plastic and aluminum. The Atlas with Hybrid Pellet + Filament Extrusion System can be used for dual material prints, such as soluble support material and high-performance model material and provides the ultimate flexibility in choosing the right extrusion technology for each application.

Founded in 1970, and incorporated by Katoen Natie in 1999, J-Tec has been active as a supplier of automated material handling systems and process engineering solutions for over 50 years. Thermoplastics. At Aircraft Extrusion Company we pride ourselves with the ability to provide not only an extensive range of aerospace aluminum shapes in 2024 and 7075, but as a vertically integrated company our capabilities expand beyond material distribution but also include custom shapes, fabricated extruded shapes and cnc prototype machining specializing in track design and supply. Dedicated to Advancing the Effective Use of Aluminum Extrusion in North America. Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. In the work of Leonardi et al. Process of Blown Film Extrusion. Learn More. Lastly, it can be said that the extrusion process is widely used to make plastic materials. In extrusion, the materials are subjected to heating, mixing, and shearing, resulting in physical and chemical modifications during their passage through the extruder [309]. The compressive force allows large deformation compare to drawing in single pass. material alongside an opaque material, to produce sheet to make thermoformed trays. Explore pullers, cutters, coilers, and more. Order Online 724-584-5500 Ethic code; 1988 Extrusion auto-die for plastic material.

CPM Extrusion Group is a global leading manufacturer of twin-screw extrusion equipment and systems. To aid in understanding the aluminum extrusion process think about a Play-Doh Fun Factory and how it works. Highly recognized for its quality, low maintenance and outstanding customer service. Owing to a continuous extrusion process, the extruder serves a high productivity system, which can provide higher efficiency for the food manufacturing process. This process is similar to drawing process except drawing process uses tensile stress to extend the metal work piece. Extrusion is a process where a material is pushed through a tool with a specialized shape called a die, producing continuous objects of a fixed cross sectional profile. The Aluminum Extruders Council (AEC) is an international trade association dedicated to advancing the effective use of aluminum extrusion in North America. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The Editors of American Journal of Ophthalmology in conjunction with the Elsevier Office of Continuing Medical Education (EOCME) are pleased to offer an AMA PRA Category 1 CreditsTM credit program for registered American Journal of Ophthalmology physician reviewers ("reviewers") who complete Plastics Extrusion. It also blocks and reduces contaminant microorganisms. 2000 Calibration device per extruded sections air cushion 2009 Thermic Solar Panel in extruded thermoplastic material. extrusion with cylinders into sheets (0.520 mm The lifecycle of our extruded products begins at the raw material stage, where we use only premium quality aluminium ingots to ensure reliability.

Call or contact Plastic Extrusion Technologies today to learn more about ABS material and our plastic extrusion services. Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic.A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. The ram exerts force on one side of the work piece, while the forming die, through which the material is extruded, is located on the opposite side of the chamber.

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Spiratex has been a leading custom plastic extrusion industry since 1955. The toughest grades have the highest molecular mass, but are more difficult to process. Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Extrusion Process The extrusion process converts a solid plastic feedstock material into a molten viscous fluid, and then to a finished solid or flexible film product for practical use. A.A. Refaat, in Comprehensive Renewable Energy, 2012 5.13.4.7.4(iii) Extrusion Extrusion process is a novel and promising physical pretreatment method for biomass conversion to ethanol production. Extruder Parts The use of aluminum extrusion in product design and manufacturing has increased significantly in recent decades. These many decades of experience and international expertise make us an established partner for customers in food and chemical industries around the globe. At ECS, we understand your success is a continuous process. To simplify the process of finding the material best suited for a given part or product, lets look first at the two main types of plastic: thermoplastics and thermosets. Conair's extrusion auxiliary equipment for plastics processing can improve your efficiency and product quality. SABIC has more than 33,000 employees worldwide and operates in more than 50 countries. Polymer resin, often in the form of beads, is loaded into a hopper and fed into a heated barrel with a screw. CME Information and Guidelines for Manuscript Review.

Electro nickel plating, also known as nickel electroplating or nickel electro-deposition, is becoming an increasingly popular process for a variety of different manufacturing applications. The Institute comprises 33 Full and 13 Associate Members, with 12 Affiliate Members from departments within the University of Cape Town, and 12 Plastics extrusion is a continuous high-volume manufacturing process, in which raw plastic is melted and formed into a continuous profile. According to a recent report from Technavio, between 2019-2023 the growth of the global aluminum extrusion market will be accelerating with a Compound Annual Growth Rate (CAGR) of almost 4%.. Perhaps youve heard of this manufacturing process and are wondering Composite Extrusion Modeling (CEM) is an advanced material extrusion additive manufacturing technique for low-cost rapid production of complex parts. Some benefits of calendering include control over product thickness and the ability to produce parts thinner and wider than with the extrusion. Who We Are. In the automotive industry, the extrusion process is also used to form the desired type of material by using brittle materials. Hybrid Pellet + Filament Extrusion is available on all Atlas systems. Advantages of the material extrusion process include use of readily available ABS plastic, which can produce models with good structural properties, close to a final production model. Electric current is generated by the flow of negatively charged electrons, positively charged holes, and positive or negative ions in some cases. The first step is to melt the polymer in an extruder. The aluminium ingots are then melted and cast into billets of the required size. AEC is committed to bringing comprehensive information about extrusion's characteristics, applications, environmental This process works best to produce sheets or films of rubber. They can also use their silk to suspend themselves, to float through the air, or to glide away from predators.Most spiders vary the thickness and stickiness This process starts by feeding plastic material (pellets, granules, flakes or powders) In low volume cases, this can be a more economical method than using injection moulding. Extruded material emerges as an elongated piece with the same profile as the die opening. The Atlas with Hybrid Pellet + Filament Extrusion System can be used for dual material prints, such as soluble support material and high-performance model material and provides the ultimate flexibility in choosing the right extrusion technology for each application. The shape of the die is a cross-section of the final part. ALUMINIUM EXTRUSION . Typically, granulation involves agglomeration of fine particles into larger granules, typically of size range between 0.2 and 4.0 mm depending on their subsequent Direct extrusion is a similar metal extrusion process to the one illustrated in figure 208. The surface of the metal is converted to aluminum oxide as a. Powder Coating. This process includes doors, windows etc. Blown film extrusion can be complex so we will now explain each step of the process in detail! Extrusion equipment consists of a plasticizing extruder, die assembly, a cooling assembly, and haul-off or winding equipment. The entire design and production process and activities are performed inside the company: this factor is the basis of our know-how. Vented Extrusion A vented extruder is an extruder that contains a vent, which is used to extract volatiles from a plastic material during the extrusion process.

In direct, or forward extrusion, the work billet is contained in a chamber. ALUMINIUM Aluminium is an extraordinarily versatile material. The water (moisture) and Once the material passes through cooling rollers, it must be vulcanized. ECS is a parts supplier in the polymer extrusion industry. The range of forms it can take (castings, Anodizing.