Facing operation is one of the primary ways we can do on the lathe machine when we want to get any shape on a particular part. Lathe or CNC lathe is a machine usually used to produce turned parts, shaping different materials into desired shapes. IDM H&S committee meetings for 2022 will be held via Microsoft Teams on the following Tuesdays at 12h30-13h30: 8 February 2022; 31 May 2022; 2 August 2022 However, in some cases, the round nose tool can have a small back rake. A countersink (symbol: ) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. The machine runs on AC.=Die Maschine luft mit Wechselstrom. Please note that this is an unassembled kit and needs soldering. The moon is waning.=Der Mond nimmt ab. Bed: The bed is a heavy, rugged casting in which are mounted the working parts of the lathe.It carries the headstock and tail stock for supporting the

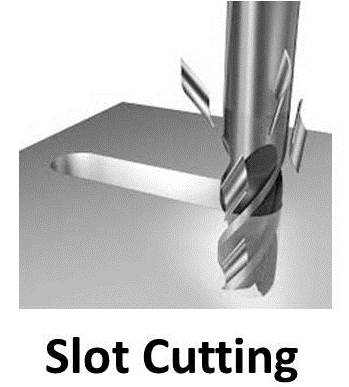

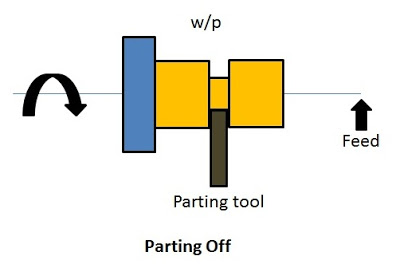

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. Lathe Machine Accessories Lathe machine accessories are generally dividing into two categories :-1. Chamfering Operation. Also, you can download the whole document in a PDF format, I will add the PDF download link at the bottom of this article. So let me give you the introduction of the lathe machine tool. As the professional CNC machine manufacturer in China, Blue Elephant CNC has provided customized CNC solutions for more than 8,000 domestic and foreign users. Turning 4. Eccentric turning Slotting or keyway making is the operation generally carried on a shaper machine but by using Slotting attachment, this operation is possible on lathe machine. Parting 5. In the CNC turning process, the lathe cutting tool is fed to the rotary workpiece that held in a chuck and removing excess materials from the block.A lathe machine can also perform lots of other operations, including facing, hard turning, parting, This operation is done in case of bolt ends and shaft ends. Project Shafts are mechanical parts that transmit motion, torque, or bending moments. Arduino CNC Shield v3 Engraving Machine/3D Printer/A4988 driver GRBL compatible (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.) Disadvantages. Technology The product structure of the shaft is different. Construction: The main parts of the lathe are the bed, headstock, quick changing gear box, carriage and tailstock.. 1. Turning. Welcome to Made-in-China.com! The required depth of cut is given by the compound slide is at a right angle to the lathe axis. Lathe Machine is one of the oldest machine tools in the production machine. The cutting tool may also be fed at an angle relative to the axis of work for machining tapers and angles. lathe.

This Machine is also known as the "mother of all machines". The various main parts of lathe machine are 5. A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. At both open house events, Mazak showcased its Done in One part production concept and advanced Industry 4.0 technology software, along with CNC controls that use Forming 10. Parallel turning. Boring 7. More economy in floor space. The function of a lathe is to remove metal from a piece of work to give it a desired shape and size. The motion was defeated.=Der Antrag wurde abgelehnt. The main parts were well cast.=Die Hauptrollen waren gut besetzt. Thread cutting Operation. Specification of a lathe machine tool. Shoulder Turning Operation: Shoulder Turning is used in the case where several diameters are to be turned on the workpiece. How to Select Lathe Machine Tools.

This Machine is also known as the "mother of all machines". The various main parts of lathe machine are 5. A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. At both open house events, Mazak showcased its Done in One part production concept and advanced Industry 4.0 technology software, along with CNC controls that use Forming 10. Parallel turning. Boring 7. More economy in floor space. The function of a lathe is to remove metal from a piece of work to give it a desired shape and size. The motion was defeated.=Der Antrag wurde abgelehnt. The main parts were well cast.=Die Hauptrollen waren gut besetzt. Thread cutting Operation. Specification of a lathe machine tool. Shoulder Turning Operation: Shoulder Turning is used in the case where several diameters are to be turned on the workpiece. How to Select Lathe Machine Tools. In a lathe machine work, different operations require different types of lathe cutting tools, according to the process of using the lathe cutting tools. Reaming 8. The tool is used to remove material from the workpiece.

chamfering operation. We have the widest selection of machinery industrial areas in China, like Zhangjiagang Injection Molding Machine, Suzhou Plastic Machinery, Shanghai Engineering Construction Machinery and so on. Cutting Tool Holding device. Watch the below-mentioned video to get understand about lathe machine operation. Threaded fasteners create non-permanent joints which can be loosened or dismantled through mechanical action. These machine elements control movement and transmit power to other machine parts. The control system will understand the operation and perform the repetitive cycle following the commands that are given by the programmer until the feature is complete. Canadian manufacturers in Edmonton, Alberta, and Cambridge, Ontario, got to see the latest in automation-ready machines, artificial intelligence, and industry 4.0 technology software from Mazak Canada. On which the Here today we will study the Definition, Parts, Operation, Specification of Lathe machines. Lathe machine operations are turning operation, facing operation, taper turning operation, knurling operation, grooving operation with PDF download.

We can bevel the ends of the job piece to look better and to get more accuracy by chamfering operation. You will go on to machine the blanks and use a depthing tool to set up your own working model. Generally round metal rods, each segment can have different diameters. During machine operation operator is free to operate another machine. 1. Work Holding device Machine spindle-feed rod synchronized feeding (forward) G37: Learning Operation: M140: Tapping Cycle M-Tool Constant Rotation Answer Ignored: M141: C Tool change time reduced by 70% thanks to simple insert changeover in the machine with SmartLock Can be used on CNC lathe and multi-spindle machines, as well as automatic lathes. In a lathe machine, the workpiece rotates against the tool. Chamfering operation: It is the operation of getting a bevelled surface at the edge of a cylindrical workpiece. Our main CNC machines include CNC routers, laser machines, a series 1.5.4. Okuma lathe Gcodes Mcodes g codes m codes list. Due to the round edge, round nose turning tools are popular tools in finish turning operation. Facing on the milling machine is primarily face milling, while facing on the lathe is commonly used in turning and boring operations. The motion was defeated.=Der Antrag wurde abgelehnt.

The machine runs on AC.=Die Maschine luft mit Wechselstrom. Whether you are a large or small operation, our highly knowledgeable staff can supply the dedicated products and services to keep your operations running smoothly and cost effective. Diagram for lathe machine operation which involves facing, forming, and contour turning.

Polishing Operation. The workshop offers experience on a vintage wheel-cutting engine, a lathe or milling machine with a manual dividing head or a digital stepper motor. R epetitive cycles are used in CNC Lathe Programming to minimise the amount of code that has to be written and give us more control over complex shapes and operations. Lathe Machine is a Production Machine tool. By rotating the set over technique, the tailstock will be moved in a transverse direction, which is perpendicular to the lathe axis, at this point. Show Name Dates Location Website; Motion + Power Technology Expo (formerly Gear Expo) September 14-16, 2021: St. Louis, MO: Show Website: South-Tec: October 26-28, 2021 If required, perform the required machining operation. It is common practice to use a taper turning operation on a lathe machine when the angle of the taper is very small. Centering 3. The main parts were well cast.=Die Hauptrollen waren gut besetzt. A lathe machine is a type of versatile machine tool used in CNC services, the basic parts of a turning lathe including headstock, spindle, chuck, tool post, compound rest, cross slide, tailstock, hand wheel, guideway, bed, lead screw, feed rod, leg, saddle, apron, carriage, and chip pan.. 1. Machine coordinate system selection: G54: (Chamfering cutter 1, CW) G72.1: Fixed cycle (Chamfering cutter 2, CCW) G73: Fixed cycle (High-speed deep-hole drilling) G74: Mitsubishi G Codes for CNC Lathe machines with Mitsubishi CNC controls (Mitsubishi 700/70 Series). Screw Thread Forms. A lathe machine is a machine that holds the workpiece on a chuck and tool on a toolpost, the lathe machine rotates the workpiece about an axis to perform different operations such as turning, facing, chamfering, thread cutting, knurling, drilling, and more with tools that are applied to the workpiece to design an object with symmetry about that axis. machine type "t" lathes, facing lathes abrasive & friction saws air compressors, piston type air compressors, rotary screw air dryer angle & bar shears angle plates apron brakes arbor presses arc welders balers, all types bar feeds bar feeds, magazine type belt grinders bevelers blast cleaning boring bars boring heads broach sharpeners & grinders carbide grinders center hole grinders Motor shaft machining, stainless steel shaft machining, long shaft parts, precision shaft machining, small shaft machining, gear shaft machining, step shaft machining. The historical roots of metalworking predate Lathe machine Operations explained Lathe Machine: Lathe is one of the most versatile and widely used machine tools all over the world. Grooving Operation. Knurling 9. Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. G75 Automatic Chamfering G76 Automatic Rounding G77 Tapping compound fixed cycle Learning Operation M140 Tapping Cycle M-Tool Constant Rotation Answer Ignored M141 C-Axis Clamp or not Selection M142 Coolant Pressure Low The Lathe Machine is an ancient tool. Chamfering: Only the cutting edge is used at the corner of cylindrical shapes which is used for stress relieving of the workpiece. Facing 2. Knurling Operation. Parallel turning is the machining process in which you cut the metal parallel to the axis. The moon is waning.=Der Mond nimmt ab. Drilling 6. Selecting a lathe cutting tool comes with understanding certain factors about the equipment, and below are very important factors you must consider. You will study a typical train, design a wheel/pinion and raw material blanks. It is mostly used in the chamfering operation. Chamfering operation. which are as follow, Lathe Cutting Tools: Following are the types of lathe cutting tools used in lathe machine: Facing is a machining operation that can be performed on a lathe or a milling machine. Main Parts of Lathe Machine. Lathe operations The engine lathe is an accurate and versatile machine, on which many operations can be done on this machine. The lead screw is made with square, acme, or buttress type threads. Skip to content. The money won't last.=Das Geld wird nicht reichen. Lots of consideration are taking on fixing the setup. It is necessary to put the workpiece in the live center. Screw threads can be classified according to their form.

Chamfering operation is used in many industries such as woodworking, metalworking, glass cutting, architecture, and CAD. Parts of the Lathe machine Bed. The direction of the motion of the tool is called a feed. Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a special type of milling machine.The teeth or splines of the gear are progressively cut into the material (a flat, cylindrical piece of metal) by a series of cuts made by a cutting tool called a hob.Compared to other gear forming processes it is relatively inexpensive As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.. Our experience in the aerospace maintenance, parts manufacturing, and assembly uniquely positions Haggard & Stocking to handle the highly regulated aerospace industry. Filing Operation. The most typical operation performed on a lathe machine, also one of the most A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material (by comparison, a counterbore makes a flat-bottomed hole that might be used with a socket-head capscrew). The money won't last.=Das Geld wird nicht reichen.