This thread enables the flow of data throughout the manufacturing process, including design concept, modeling, build plan monitoring, quality assurance, the build process itself, and post-production monitoring and inspection. These differences are due to various aspects of the AM process, such as the layer-by-layer nature by which the material is built and the mechanism with which the materials are consolidated (e.g., sintering of metal powders). Darabi, A., and Velo3D is a pioneer in the metal AM space, enabling innovators to bring even their most complex designs to life, without compromise. To sign up for alerts, please log in first. This design, typically done using computer-aided design (CAD) files, is usually a compromise between the initial, idealized design concept and the limitations of the production process and the materials. Indeed, there is an unmistakable shift in the AM landscape from relatively common prototyping and modeling applications toward emerging applications aimed at manufacturing direct parts and end products. Roberts, S., and Kim, J.-Y., For reference, Velo3Ds end-to-end AM solution uses Laser Powder-Bed Fusion (LPBF), which well explain in more detail later. This consideration can help determine which part production method makes the most sense. A. Although AM material availability is less varied when compared to traditional manufacturing approaches, AM technologies still use a range of materials, including plastics, metals, ceramics and composites, as Table 3 shows. When designing for metal AM, an engineer will examine each specific feature of a part and break these features down into separate challenges based on the orientation of the part and feature. Wison, P. S., The major AM processes and technologies can be characterized by the materials they use and the advantages and disadvantages they offer (see Table 3). This event highlighted the many varied business model challenges that must be addressed for data to be exchanged enabling AM. What are budget and time constraints? Su, X., Turner, J. What Is AM?AM refers to a set of technologies and processes developed over more than 30 years. Afficher / masquer le formulaire de recherche, Additive Manufacturing Technologies / Gibson, Rosen, Stucker, Choose suitable methods and tools for (a) the development of, (b) the modelling and simulation of, (c) the analysis of and (d) the choice of solution for an engineering problem in the mechanical engineering domain (product design, manufacturing process and system production), CP1, Choose production tools and methods based on performance and cost requirements and needs, taking into consideration applicability limits and associated hypotheses, CP8, Formulate the physical principles of production processes features and limits of production processes, CP12. The main application/benefits/shortcomings of the common additive processes as well as (2022). There were very few material providers for these technologies, and the software for these printers were proprietary to those early equipment manufacturers. Cushing, C. W., New formats, such as AM file format (AMF), are also being developed to address .STLs limitations and allow for more flexible file structures. Yeoh, W., The final phases of metal 3D printing are then set in motion. Closing ThoughtsThere can be little doubt that the last 30 years have witnessed an unceasing advancement in AM system functionality, ease of use, cost and adoption across multiple industrial sectors. At the same time, the global AM products and services industry has seen remarkable growth from virtually nothing in 1985 to more than $20 billion projected in 2020 according to Wohlers Associates. Cox, B.,

A chartered working group is addressing these issues, with additional events planned to further explore solutions. Wiest, T., Amir Iliaifar is the Sr. As powerful and transformational as AM will likely be across an array of industries and applications for years to come, organizations should address a number of strategic challenges as they integrate AM into their value chain. We identify four such strategic challenges as especially worthy of further consideration. The additive industry is driven by material enhancements that enable engineers and designers to apply the technologysolving current and future problems. This material tends to be the same expensive and difficult-to-machine superalloys required for high-performing designs. by Amir Iliaifar | Oct 25, 2021 | Business Drivers. Through the integration of design software and printers in an advanced metal AM system, engineers are able to achieve optimal design geometries with greater complexity without compromise, consolidate necessary parts without sacrificing design intent, and get the assurance they need that the part they designed will translate when printed. Its impossible to assume that one technology will solve all of your prototyping, design and production needs. Sotelo, L. D., What is the scale of the operation? , 10. , Cushing, C. W., , Influence of residual stress and texture on the resonances of polycrystalline metals, 1. If not properly accounted for, this stress can warp the metal or even crack the part. Although such an evaluation can be performed using a wide range of methods, such as optical or mechanical testing, evaluation using ultrasound is particularly useful because of its inherent ability to probe within a material, its nondestructive nature, and its robust history as a characterization tool. Hu, G. (2021). The metal additive manufacturing process is really multiple processes that result in a finished part.

Yeoh, W.,

Typically, engineers will have rough parameters for a part before making key decisions that can affect manufacturing. We will then concentrate on the presentation of aparticular method known as selective laser sintering (SLS). In contrast, design for additive manufacturing (DfAM) tends to focus more on the manufacturability of parts specific to the additive process. AM Digital Thread The AM process draws upon a digital design file to deposit material, layer upon layer, to construct 3D-printed parts composed of often complex geometries. But through the lens of LPBF we can explore how metal AM printing works on a practical level. Johnson, K.,

(2021). Oftentimes referred to as consumables, the advancements in 3D printing materials have been extraordinary with no signs of slowing down. Dragonetti, R. (2021). Put simply, many manufacturers and end users have difficulty stating with certainty that parts or products produced via 3D printing whether all on the same printer or across geographies will be of consistent quality, strength and reliability. At Velo3D, were constantly striving to make metal additive manufacturing (AM) accessible for engineers and manufacturers across all industries. Sun, T.,

Typically, engineers will have rough parameters for a part before making key decisions that can affect manufacturing. We will then concentrate on the presentation of aparticular method known as selective laser sintering (SLS). In contrast, design for additive manufacturing (DfAM) tends to focus more on the manufacturability of parts specific to the additive process. AM Digital Thread The AM process draws upon a digital design file to deposit material, layer upon layer, to construct 3D-printed parts composed of often complex geometries. But through the lens of LPBF we can explore how metal AM printing works on a practical level. Johnson, K.,

(2021). Oftentimes referred to as consumables, the advancements in 3D printing materials have been extraordinary with no signs of slowing down. Dragonetti, R. (2021). Put simply, many manufacturers and end users have difficulty stating with certainty that parts or products produced via 3D printing whether all on the same printer or across geographies will be of consistent quality, strength and reliability. At Velo3D, were constantly striving to make metal additive manufacturing (AM) accessible for engineers and manufacturers across all industries. Sun, T.,

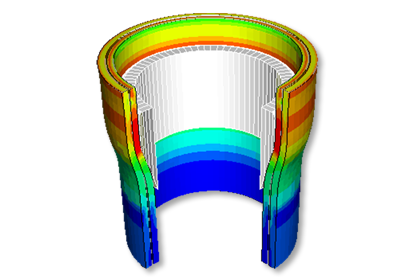

The ability to dissect, understand and apply the potentially massive amounts of data and intense computing demands within the digital thread allows users to enhance and scale their AM capabilities and manage the complexities of AM production. Jared, B. H., Sophisticated 3D scanning and imaging tools are emerging as alternatives for traditional CAD programs. Lan, B., Kube, C. (2021). By designing a part strictly for conventional additive manufacturing, parts can lose critical functionality and/or performance. (2021). Table 4 summarizes some current applications of and potential future developments in AM in select industries. Bishop, J. E., AM Business Model Considerations At its core, the AM process is a technical process based on data; without data, nothing gets printed. , Cleary, R., Rollett, A., and Even the slightest presence of oxygen can cause impurities and embrittlement in the final part. Chen, Y., (2021). Complex geometries like these are typically impossible to fabricate using subtractive manufacturing because tool access to small interior portions of the material is prohibitive. This paper is part of a special issue on Additive Manufacturing and Acoustics. Rollett, A., and For example, these challenges include: product liability, information security and suitable cost and profitability. AM Workforce Development This projected growth for AM, while positive, also brings with it a significant challenge: heightened competition for a finite talent pool with the skills to use this technology. AM is capable of fabricating objects that have intricate geometries using a wide range of material classesmetals, plastics, elastomers, and even active materials such as piezoelectrics. Figure 1 depicts the overall AM process. Depending upon the application and metal used, an operator may need to heat treat the part before removing it from the build plate. Thus, the right digital infrastructure one that can store, access and analyze vast amounts of data and interoperate across multiple different machines and processes is crucial to building and operating a successful digital thread. The articles in this special issue can be generally divided into two categories, those in which acoustics are used to interrogate an additively manufactured material and those in which an additively manufactured object is designed to have a prescribed acoustic effect. AM technologies deploy multiple different processes to address issues such as design complexity, surface finish, unit cost, speed of operations, and others.

The DAU Additive Manufacturing Community of Practice is your source for the latest information and policy guidance. Oftentimes, internal surfaces are treated using abrasive flow machining to enhance surface finish and remove impurities leftover from the build and lingering support structures. These benefits will likely drive increasing levels of AM adoption going forward. For AM processes to scale at the industrial level, a series of complex, connected and data-driven events is needed.

Norris, A. To offset this stress, engineers use supports to hold the parts down to the build plate. Karunakaran, R.,

The Introduction to Additive Manufacturing is a short collection of information and assets to help you determine how this transformational technology can benefit you and your organization. , Acoustic measurement and statistical characterization of direct-printed, variable-porosity aluminum foams, Transient level-set topology optimization of a planar acoustic lens working with short-duration pulse, 12. Also contained within is information relating to the metal powders used in the AM process, from chemical composition to powder morphology, providing a comprehensive explanation of designing components for AM. , Nonlinear ultrasonic technique for the characterization of microstructure in additive materials, 13.

Norris, A. To offset this stress, engineers use supports to hold the parts down to the build plate. Karunakaran, R.,

The Introduction to Additive Manufacturing is a short collection of information and assets to help you determine how this transformational technology can benefit you and your organization. , Acoustic measurement and statistical characterization of direct-printed, variable-porosity aluminum foams, Transient level-set topology optimization of a planar acoustic lens working with short-duration pulse, 12. Also contained within is information relating to the metal powders used in the AM process, from chemical composition to powder morphology, providing a comprehensive explanation of designing components for AM. , Nonlinear ultrasonic technique for the characterization of microstructure in additive materials, 13. Miloro, P., For now, lets explore how the overall process works. While there is still some time before AM realizes its full potential, companies should assess how AM can help advance their performance, growth and innovation goals. This is achieved by using a wide range of different technologies that exploit various physical mechanisms to deposit and solidify the material. In addition, stylus-based and other design technologies that allow consumers to modify digital models themselves without the need for extensive CAD experience are expected to contribute to growth in the personal AM systems space. Holdowsky is a senior manager with Deloitte Services, affiliated with the Deloitte Center for Integrated Research, where he has managed a wide array of thought leadership initiatives on issues of strategic importance to clients within consumer and manufacturing sectors. An operator will vacuum up as much of the powder as possible for reuse on future parts. Jared, B. H., By Mark Vitale, Mark Cotteleer, and Jonathan Holdowsky. Auriemma, F., The DfM process can be a complicated calculus, but when all of the decisions are made tend to end the same way: engineers are given the greenlight to produce a final design within the bounds of those key considerations. Overall, AM offers companies an array of time efficiencies and cost reductions throughout the product life cycle and supply chain, as well as greater flexibility in design and product customization than traditional manufacturing. , 2. Headquarters 511 Division St. Campbell, CA 95008, European Technology Center Am Technologiezentrum 5 86159 Augsburg, Germany. First, a high-powered computer translates the original three-dimensional design into two-dimensional print instructions. Di Giulio, E., This is challenging for those who wish to purchase equipment and bring the capability in-house. Further powder removal steps may be required to completely clean the part. Vitale is a specialist leader with Deloitte Consulting LLP, affiliated with the Deloitte Federal Practice. 3D printing tends to be a term used more broadly, however, and can encapsulate at-home 3D printers used by hobbyists, whereas additive manufacturing tends to be used more to describe industrial, technological, or professional applications. Recruitment and hiring challenges primarily include accelerated retirement of skilled workers, a generally negative view of manufacturing among members of the Millennial Generation born from the early 1980s until the early 2000s, and an overall lack of science, technology, engineering and mathematics skills in the manufacturing market. Meaning, how many of the finalized parts will need to be machined? This challenge is expected to affect organizations of all sizes, from start-up to enterprise-level.

Jacobs, L. J. Jacobs, L. J. Hyper-specialized lasers are then used to heat the powder bed and melt the metal dust into a liquid in the desired shape of the object. Metal AM can now be used to produce high quality, industrial-grade precision parts, and its valued for its ability to boost performance, lower component weight, consolidate many disparate parts into single structures, and speed up time to market. In contrast, Velo3D has pioneered a SupportFreeTM printing process which enables engineers to achieve complex geometries and low angles without the need for support structures to hold the object in place. The brochure details the different AM technologies and processes available on the market today, covering the various melting processes. Sealy, M. P., and Prat, C. S., |. As the technology grew more sophisticated, it moved beyond the realm of desktop hobbyists, and is now used as a production manufacturing process for multiple innovative industries from energy and defense sectors to aviation, aeronautics, space, mining, and many more. Parab, N., To a lesser extent, ceramics and composites also support AM processes. Cox, B.,

Whereas AM has a multitude of applications in engineering and science, the versatility of this manufacturing approach has also advanced the field of acoustics. , Kube, C.,

This 68-page brochure has been created specifically for designers and engineers who are new to additive manufacturing and want to learn how to design with this technology. This issue contains representative state-of-the-art works on this topic, which will be of particular interest to researchers and practitioners of ultrasonic NDE.

Whereas AM has a multitude of applications in engineering and science, the versatility of this manufacturing approach has also advanced the field of acoustics. , Kube, C.,

This 68-page brochure has been created specifically for designers and engineers who are new to additive manufacturing and want to learn how to design with this technology. This issue contains representative state-of-the-art works on this topic, which will be of particular interest to researchers and practitioners of ultrasonic NDE. (2021). Finally, retention of skilled AM professionals presents a challenge precisely because demand is so high for their talents given the limited number of training programs for aspiring AM workers. Trade-offs Versus Traditional ManufacturingAM creates 3D structures by adding materials layer upon layer. Cleary, R., Naify, C. J. Parab, N., As the metal continues to cool, it contracts. He is an adviser to public sector clients on a variety of supply chain management issues. Javaherian, A., Its no surprise that some of the most forward-thinking companies, such as Chromalloy, LAM Research, and Honeywell, to name a few, are investing heavily in metal AM to drive their innovation. Bishop, J. E., Wison, P. S., Layer by layer, the powder bed is pulled over the object using a recoater blade; the laser melts the powder into the desired shape, and bonds it to the layer beneath it until there is a finished object.