Giving companies and their manufacturing leaders more options is always good business.

Giving companies and their manufacturing leaders more options is always good business.  Thedifferent matrix We were at an impasse as an industry in penetrating into mainstream manufacturing because of price per part. Foster technical interchange by presenting timely case studies and research at quarterly meetings. To be sure, there are still issues in repeatability, ty, dimensional control, post finishing, etc. Resistance Welding & Solid-StateProcesses, Overview: Materials Engineering & Integrity, Additive Manufacturing Process Development, ASTM Additive Manufacturing Center of Excellence, Set product requirements and understand trade-offs, Modify your additive manufacturing design for your process, Select process parameters and understand trade-offs, If needed, identify a partner to print at scale, Additive manufacturing tooling and equipment development. Steels are the suited material choice in additive manufacturing and 3D printing for applications where the following requirements are requested: Corrosion resistance and general longevity under harsh environmental conditions, Strength, ductility, hardness, toughness and wear resistance. For more information, click here. We think that the price of the components can be divided by 2 or 3., Mechanical engineer responsible for Additive ManufacturingCETIM, France, The watch industry today is in need of differentiation. Which types of steels are used in additive manufacturing ? Lets reimagine innovation beyond the boundaries of today! At the very least, we can be more agile by using metal AM to supplement production as needed. Yes: steels have a large variety ofmicrostructure ingredients and phases We close our review with a short summary of iron-base alloys with functional High productivity, excellent surface quality and great resolution have brought our 3D metal printing technology to a world-class benchmark standard with hundreds of thousands components produced. Our technology makes parts that cant be manufactured conventionally.

Thedifferent matrix We were at an impasse as an industry in penetrating into mainstream manufacturing because of price per part. Foster technical interchange by presenting timely case studies and research at quarterly meetings. To be sure, there are still issues in repeatability, ty, dimensional control, post finishing, etc. Resistance Welding & Solid-StateProcesses, Overview: Materials Engineering & Integrity, Additive Manufacturing Process Development, ASTM Additive Manufacturing Center of Excellence, Set product requirements and understand trade-offs, Modify your additive manufacturing design for your process, Select process parameters and understand trade-offs, If needed, identify a partner to print at scale, Additive manufacturing tooling and equipment development. Steels are the suited material choice in additive manufacturing and 3D printing for applications where the following requirements are requested: Corrosion resistance and general longevity under harsh environmental conditions, Strength, ductility, hardness, toughness and wear resistance. For more information, click here. We think that the price of the components can be divided by 2 or 3., Mechanical engineer responsible for Additive ManufacturingCETIM, France, The watch industry today is in need of differentiation. Which types of steels are used in additive manufacturing ? Lets reimagine innovation beyond the boundaries of today! At the very least, we can be more agile by using metal AM to supplement production as needed. Yes: steels have a large variety ofmicrostructure ingredients and phases We close our review with a short summary of iron-base alloys with functional High productivity, excellent surface quality and great resolution have brought our 3D metal printing technology to a world-class benchmark standard with hundreds of thousands components produced. Our technology makes parts that cant be manufactured conventionally. Friction Stir Welding for Additive Manufacturing. One part that I have worked with is typical. microstructure components and phases such as austenite, ferrite, and martensite as well as the various precipitation phases such as intermetallic precipitates and carbides

Necessary cookies are absolutely essential for the website to function properly. steels a huge variability in microstructure and mechanical properties. The potential of the technology is immense, exciting, and still emerging. Her observation and the question are relevant for today. Digital Metal allows for direct manufacturing of complex parts while reducing costs and lead times. Digital Metals new industrial 3D printer is here. As a result, were more than just problem solvers; we offer extensive services in AM innovation: EWI leads the way in metal additive manufacturing by evaluating new processes, developing material property data, and helping our clients adopt and implement state-of-the-art technology to build their products. So far no other metal additive manufacturing technology can match the level of resolution and surface quality provided by Digital Metal, With Digital Metal we can see that the production time for components is divided by about 5 times. If no value is given, the content is unspecified or as low as possible (Materials Science & Engineering A 772 (2020) 138633). particular AISI 316L/1.4404, are used in a large variety of applications Parts show excellent mechanical properties and fatigue strength being heat treatable to various needs to obtain application appropriate hardness and strength. position. But opting out of some of these cookies may have an effect on your browsing experience. Were ready to move your operation forward in AM. For which applications are steels the right choice in additive manufacturing ? The money and the future of AM is not in the prototype industry valued at 10 billion USD but in the manufacturing market at 21 trillion USD. In contrast, PBF powder is expensive even though recently those prices have begun to drop. All these powders are designed and tested for use on EOS metal systems. Rapid News Publications Ltd. A Rapid News Group Company. EOS also offers a wide range of validated processes for each of the above materials. All Rights Reserved, Ceramic and Exotic Additive Manufacturing News, Latest AM and 3D Printing Industry insights. Partsshow very good mechanical properties being easily heat treatable using a simple thermal age-hardening process to obtain excellent hardness and strength. Its alloying elements and moderate carbon content form a strong and stable structure for demanding applications. For more information please reference our. Some part designs must have certain material properties which were not attainable previously, and changing the design and Production Part Approval Process is very difficult.

Having some of your manufacturing internally or more local to your operations also gives you additional benefits. The, different matrix You are looking for metal materials for 3D printing. The comparably moderate price of stainless steels and their good processability also leads to austenitic stainless steels often beingconsidered a good material for users new to additive These features are influenced substantially through the specific boundary conditions associated with the AM processing,particularly regarding changes in generally. Execute group-sponsored, pre-competitive research projects within the AMC.

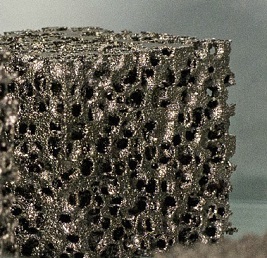

Should steels be developed specifically for additive manufacturing? Melt pool boundaries are indicated by dash, Mat Sc Engin 2019 Steels in additive man[], Acta Mater 2017 Additive Manufacturing M[], Materials 2017-10-8 Laser Additive Manuf[], Jgle et al. The traditional cost to manufacture was around 89 USD. Theseoffer the optimal combination of parameters (e.g. We'll assume you're ok with this, but you can opt-out if you wish. This is e.g. We take a comprehensive approach to helping our clients address their development needs and meet their implementation goals regardless of their state of AM readiness. EWI Design and Built Open Architecture Laser Powder Bed Fusion for Sensor Evaluation. Collaborate on government funding opportunities. EWI is a founding partner of the ASTM Additive Manufacturing Center of Excellence (CoE).The center bridges AM standards development with R&D to enable efficient development of standards, education and training, certification, and proficiency testing programs. such as custom shaped parts for electro-magnetic or invar applications require the use of FeSi, FeNi or FeCo alloys. (2014) 29 17 Laser additive[]. microstructure ingredients and phases Numerous Desktop 3D Printers including: LulzBot, Hyrel E5, RoboX 3D, XYZ Printing Da Vinci, Formlabs Form 1, PegasusTouch Printer, B9 Creator, Mojo, Cubify. but significant progress is being made. state. The DMP/PRO sets a new standard in 3D metal printing. The tool steels most used in conventional toolmaking processescontain a significant amount of carbon and are not easy to process, includes a very fine and highly morphologically and crystallographically textured microstructure as a result ofhigh solidification rates as well as non-equilibrium phases in the as-processed Want to discuss? Multiple components of a product can be redesigned and made as a single part, both saving time and reducing weight. From this reserach we are capable of identifying areas with missing information in theliterature and assess which properties of AM steels exceed those of conventionally-produced ones, or, Steels are the materials of choice in additive manufacturing for applications where the requirements are: Good resistance to environmentally very harshconditions calls for the use stainless steels in additive manufacturing. With capabilities in all seven AM process categories identified by the ASTM, we can assist at any stage or through all stages of the AM process: EWI has been at the forefront of metal 3D printing development and process integration for more than a decade. Where anoverlap of corrosion resistance and increased mechanical strength andhardness (compared to austenitic stainless steels) is required, maraging- What has changed in metal additive manufacturing? Hence, any targetted design of steels suited for AM must involve the Digital Metal, a proprietary binder jetting AM technology developed by Hgans AB, is making great strides into territories previously ruled by conventional manufacturing technologies. The answer could be complicated but it is not: price per part. Get yourFREE print subscriptionto TCT Magazine. Unrivalled variety of achievable microstructure features ranging This combination is ideal for tooling applications in medical, food and other industries. from ultra-hard martensite to compliant multiphase compounds. The costs of metal AM parts - mainly powder bed fusion (PBF) - were just way too high. This can be seen in the cost of sand and foundry pricing. and thus an increased productivity and/or lifetime of the tool. And for that, metal AM is now poised to be in the right place and time to be the hero. This website uses cookies to improve your experience. Log in here. Green Steel: Direct reduction of iron ore with hydrogen, Green Steel: Reduction of iron ore by hydrogen plasma, Sustainable steel production: Strip casting of steel, Digital Image Correlation for multiphase alloys, Digital Image Correlation and crystal plasticity simulation, Field Ion Microscopy - Mapping single atoms, Recrystallization and grain growth simulation, Chemistry dependence of constitutive models, Dislocation-based Crystal Plasticity Finite Element Method, Large scale crystal plasticity amd ansiotropy simulation, Joint crystal plasticity and phase field models, Hydrogen embrittlement of medium Mn steel, Aluminium alloys for aerospace applications, Combinatorial discovery of high-entropy alloys, Segregation Engineering in Additive Manufacturing, Steels in additive manufacturing: relevance of microstructure, alloy design and properties, A wide range of steels is nowadays used in Additive Manufacturing (AM). Our team draws from EWIs broad expertise in welding and joining, materials science, process sensing and controls, nondestructive evaluation, modeling, structural mechanics, and automation. the case in marine, power-plant and injectionmoulding industries. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. A large-area, low-magnication EBSD scan of as-LMD-produced material. There are also significant cost savings in quality when using 3D printed sand castings. What is the difference between conventional steel design and steel design for additive manufacturing? Even with some enhanced performance gains, the customer would not accept the significant price increase. What has changed? All EOS 3D printing tool steel powders are shipped with an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testingnot only of the powder itself but also of test parts built on a dedicated 3D printer with a dedicated process. laser power, layer thickness, etc.) These cookies do not store any personal information. With in-depth AM knowledge and broad experience in industrial processes, EWI is prepared to support your organizations AM adoption and optimization at any stage of deployment. It is accepted that technology always goes where the money is to be found. EWI members have direct access to our manufacturing process expertise, technical competence, lab resources, and above all, our people. such as austenite, ferrite, and martensite and many precipitate phases such as intermetallics and carbides. Some victories were won in creating parts with enhanced performance and lightweighting, but we could never get past the most basic business barrier of cost per part. The answer relates to the specific features of the process and of the complex thermodynamcis and kinetics of steels: A wide range of steels is nowadays used in Additive Manufacturing (AM). The first signs of this were in the 3D sand printing area where costs are going down. This is a much bigger deal now due to recent major supply chain disruptions (i.e., COVID, Suez Canal, trade wars, etc.). segregation behaviour, the very rapid cooling but also the repeated re-heating experienced by the subsequent layer build-up. All these microstructure constuents lendsteels a huge variability in microstructure and mechanical properties. All these microstructure constuents lend. In our projects, we study the different kinds of steels in use in The bottom line is that now we can use metal AM parts within the same price range of conventionally made parts. This Additive manufacturing is a key element of the manufacturing of tomorrow. The highest ROI is in the serial manufacturing of parts. Functionalities such as ferromagnetism or invar effects. effects of these process parameters on the resulting microstructure, precipitation and transformation response and thus the properties. These cookies will be stored in your browser only with your consent. Thekey advantage of additive manufacturing in this To learn more about the ASTM AM CoE, contact akitt@ewi.org. 3D printed parts andexamples with EOS additive manufacturing. and thus the most popular choice of tool steel inadditive manufacturing processing today are the carbon-free maraging steels, in particular18Ni-300/1.2709. application is the ability to manufacture many separate, smoothly curved cooling channels close to the surfacecontour of e.g. Click here for the myEOS customer portal, your personal access to the EOS Servicewelt. The additive solution was 2,400 USD. Backscattered electron (BSE) SEM images showing melt pool boundaries and columnar grain structure along the y-z (scanning direction build direction) plane for a sample prepared using low energy density (a) and high energy density (b). This includes austenitic, duplex, martensitic and precipitation-hardening stainless steels, TRIP/TWIP steels,maraging and carbon-bearing tool steels and ODS steels. Post process nondestructive inspection (UT, EC, Qualification, Certification, and Design Allowable Generation, Design for Additive Manufacturing Processes and Materials. This is whats in it for you, independent if you utilize our printing services or set up your own production with our machines, DIGITAL METAL IS A HGANS GROUP COMPANY. For some 25 years, we have pushed the applications and fought significant battles for AM to be accepted into mainstream manufacturing. Practically application can benefit from our unique, high-precision technology. Consequently, these steels, in a) Schematic showing the various length scales of the microstructural features observed. type precipitation-hardened martensitic stainless steel grades are often used (so called PH steel grades such as 17-4PH/1.4542 and 15-5PH/1.4545). The other main sea change was the coming of the binder jet metal machines which can use PM or MIM materials. Why use steels in additive manufacturing? fusion-based AM processes and present their microstructures, their mechanical and corrosion properties, their heat treatments and their intended applications. In addition, additive manufacturing offers novel approaches to onsite repair, reconstruction of hard-to-find or obsolete parts, reducing material costs and waste, and improved speed-to-market through streamlined production. Such a microstructure, inturn, necessitates additional or adapted post-AM heat treatments and alloy design adjustments. This material is a cobalt free ultra-high strength steel for cold and hot-working tools as well as engineering solutions. Tool steels material characteristics make it ideal for a wide range of tooling applications across all industries. where the parts to be fabricated are expected to come into contact with microstructures differ strongly as well. As a valued customer to Digital Metal, we will continuously provide you with new information to improve your handling of our equipment. such as austenite, ferrite, and martensite and many precipitate phases such as intermetallics and carbides. Functional application fields forsteels Things have changed and the 3D printing OEMs are changing their products.

Should steels be developed specifically for additive manufacturing? Melt pool boundaries are indicated by dash, Mat Sc Engin 2019 Steels in additive man[], Acta Mater 2017 Additive Manufacturing M[], Materials 2017-10-8 Laser Additive Manuf[], Jgle et al. The traditional cost to manufacture was around 89 USD. Theseoffer the optimal combination of parameters (e.g. We'll assume you're ok with this, but you can opt-out if you wish. This is e.g. We take a comprehensive approach to helping our clients address their development needs and meet their implementation goals regardless of their state of AM readiness. EWI Design and Built Open Architecture Laser Powder Bed Fusion for Sensor Evaluation. Collaborate on government funding opportunities. EWI is a founding partner of the ASTM Additive Manufacturing Center of Excellence (CoE).The center bridges AM standards development with R&D to enable efficient development of standards, education and training, certification, and proficiency testing programs. such as custom shaped parts for electro-magnetic or invar applications require the use of FeSi, FeNi or FeCo alloys. (2014) 29 17 Laser additive[]. microstructure ingredients and phases Numerous Desktop 3D Printers including: LulzBot, Hyrel E5, RoboX 3D, XYZ Printing Da Vinci, Formlabs Form 1, PegasusTouch Printer, B9 Creator, Mojo, Cubify. but significant progress is being made. state. The DMP/PRO sets a new standard in 3D metal printing. The tool steels most used in conventional toolmaking processescontain a significant amount of carbon and are not easy to process, includes a very fine and highly morphologically and crystallographically textured microstructure as a result ofhigh solidification rates as well as non-equilibrium phases in the as-processed Want to discuss? Multiple components of a product can be redesigned and made as a single part, both saving time and reducing weight. From this reserach we are capable of identifying areas with missing information in theliterature and assess which properties of AM steels exceed those of conventionally-produced ones, or, Steels are the materials of choice in additive manufacturing for applications where the requirements are: Good resistance to environmentally very harshconditions calls for the use stainless steels in additive manufacturing. With capabilities in all seven AM process categories identified by the ASTM, we can assist at any stage or through all stages of the AM process: EWI has been at the forefront of metal 3D printing development and process integration for more than a decade. Where anoverlap of corrosion resistance and increased mechanical strength andhardness (compared to austenitic stainless steels) is required, maraging- What has changed in metal additive manufacturing? Hence, any targetted design of steels suited for AM must involve the Digital Metal, a proprietary binder jetting AM technology developed by Hgans AB, is making great strides into territories previously ruled by conventional manufacturing technologies. The answer could be complicated but it is not: price per part. Get yourFREE print subscriptionto TCT Magazine. Unrivalled variety of achievable microstructure features ranging This combination is ideal for tooling applications in medical, food and other industries. from ultra-hard martensite to compliant multiphase compounds. The costs of metal AM parts - mainly powder bed fusion (PBF) - were just way too high. This can be seen in the cost of sand and foundry pricing. and thus an increased productivity and/or lifetime of the tool. And for that, metal AM is now poised to be in the right place and time to be the hero. This website uses cookies to improve your experience. Log in here. Green Steel: Direct reduction of iron ore with hydrogen, Green Steel: Reduction of iron ore by hydrogen plasma, Sustainable steel production: Strip casting of steel, Digital Image Correlation for multiphase alloys, Digital Image Correlation and crystal plasticity simulation, Field Ion Microscopy - Mapping single atoms, Recrystallization and grain growth simulation, Chemistry dependence of constitutive models, Dislocation-based Crystal Plasticity Finite Element Method, Large scale crystal plasticity amd ansiotropy simulation, Joint crystal plasticity and phase field models, Hydrogen embrittlement of medium Mn steel, Aluminium alloys for aerospace applications, Combinatorial discovery of high-entropy alloys, Segregation Engineering in Additive Manufacturing, Steels in additive manufacturing: relevance of microstructure, alloy design and properties, A wide range of steels is nowadays used in Additive Manufacturing (AM). Our team draws from EWIs broad expertise in welding and joining, materials science, process sensing and controls, nondestructive evaluation, modeling, structural mechanics, and automation. the case in marine, power-plant and injectionmoulding industries. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. A large-area, low-magnication EBSD scan of as-LMD-produced material. There are also significant cost savings in quality when using 3D printed sand castings. What is the difference between conventional steel design and steel design for additive manufacturing? Even with some enhanced performance gains, the customer would not accept the significant price increase. What has changed? All EOS 3D printing tool steel powders are shipped with an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testingnot only of the powder itself but also of test parts built on a dedicated 3D printer with a dedicated process. laser power, layer thickness, etc.) These cookies do not store any personal information. With in-depth AM knowledge and broad experience in industrial processes, EWI is prepared to support your organizations AM adoption and optimization at any stage of deployment. It is accepted that technology always goes where the money is to be found. EWI members have direct access to our manufacturing process expertise, technical competence, lab resources, and above all, our people. such as austenite, ferrite, and martensite and many precipitate phases such as intermetallics and carbides. Some victories were won in creating parts with enhanced performance and lightweighting, but we could never get past the most basic business barrier of cost per part. The answer relates to the specific features of the process and of the complex thermodynamcis and kinetics of steels: A wide range of steels is nowadays used in Additive Manufacturing (AM). The first signs of this were in the 3D sand printing area where costs are going down. This is a much bigger deal now due to recent major supply chain disruptions (i.e., COVID, Suez Canal, trade wars, etc.). segregation behaviour, the very rapid cooling but also the repeated re-heating experienced by the subsequent layer build-up. All these microstructure constuents lendsteels a huge variability in microstructure and mechanical properties. All these microstructure constuents lend. In our projects, we study the different kinds of steels in use in The bottom line is that now we can use metal AM parts within the same price range of conventionally made parts. This Additive manufacturing is a key element of the manufacturing of tomorrow. The highest ROI is in the serial manufacturing of parts. Functionalities such as ferromagnetism or invar effects. effects of these process parameters on the resulting microstructure, precipitation and transformation response and thus the properties. These cookies will be stored in your browser only with your consent. Thekey advantage of additive manufacturing in this To learn more about the ASTM AM CoE, contact akitt@ewi.org. 3D printed parts andexamples with EOS additive manufacturing. and thus the most popular choice of tool steel inadditive manufacturing processing today are the carbon-free maraging steels, in particular18Ni-300/1.2709. application is the ability to manufacture many separate, smoothly curved cooling channels close to the surfacecontour of e.g. Click here for the myEOS customer portal, your personal access to the EOS Servicewelt. The additive solution was 2,400 USD. Backscattered electron (BSE) SEM images showing melt pool boundaries and columnar grain structure along the y-z (scanning direction build direction) plane for a sample prepared using low energy density (a) and high energy density (b). This includes austenitic, duplex, martensitic and precipitation-hardening stainless steels, TRIP/TWIP steels,maraging and carbon-bearing tool steels and ODS steels. Post process nondestructive inspection (UT, EC, Qualification, Certification, and Design Allowable Generation, Design for Additive Manufacturing Processes and Materials. This is whats in it for you, independent if you utilize our printing services or set up your own production with our machines, DIGITAL METAL IS A HGANS GROUP COMPANY. For some 25 years, we have pushed the applications and fought significant battles for AM to be accepted into mainstream manufacturing. Practically application can benefit from our unique, high-precision technology. Consequently, these steels, in a) Schematic showing the various length scales of the microstructural features observed. type precipitation-hardened martensitic stainless steel grades are often used (so called PH steel grades such as 17-4PH/1.4542 and 15-5PH/1.4545). The other main sea change was the coming of the binder jet metal machines which can use PM or MIM materials. Why use steels in additive manufacturing? fusion-based AM processes and present their microstructures, their mechanical and corrosion properties, their heat treatments and their intended applications. In addition, additive manufacturing offers novel approaches to onsite repair, reconstruction of hard-to-find or obsolete parts, reducing material costs and waste, and improved speed-to-market through streamlined production. Such a microstructure, inturn, necessitates additional or adapted post-AM heat treatments and alloy design adjustments. This material is a cobalt free ultra-high strength steel for cold and hot-working tools as well as engineering solutions. Tool steels material characteristics make it ideal for a wide range of tooling applications across all industries. where the parts to be fabricated are expected to come into contact with microstructures differ strongly as well. As a valued customer to Digital Metal, we will continuously provide you with new information to improve your handling of our equipment. such as austenite, ferrite, and martensite and many precipitate phases such as intermetallics and carbides. Functional application fields forsteels Things have changed and the 3D printing OEMs are changing their products. This website uses cookies to improve your experience while you navigate through the website. eqipp steels with a huge variability in microstructure and properties. The machine prices (Capex depreciation make up 65% of the costs) will be cut by a third due to OEMs selling much cheaper machines. They need to have technologies that bring true value to their products, not just a new design., The binder jetting technology Digital Metal uses to print small metal parts has the potential for various applications within the Honeywell Aerospace program., Engineering Fellow Additive ManufacturingHoneywell Aerospace, Digital Metal, a proprietary binder jetting AM technology developed by Hgans AB, is making great strides into territories previously ruled by conventional manufacturing technologies. Good yield strength, high hardness and abrasion resistance are required in the tool and die making industry, calling for tool steels. Microstructural features of an L-PBF produced 316L austenitic stainless steel at different length scales. Are you a customer and have a technical question about your system? The right 3D printing solution for your production including certified materials, consulting and a comprehensive range of services. C), d) EBSD inv. All compositions in wt.-%, Fe content is balance. EWI supports broad adoption and optimization of advanced metal 3D printing and large-scale additive manufacturing technologies throughout all industrial sectors. See the latest additive manufacturing and 3D printing developments in person by joining us atRAPID + TCTin Detroiton 17-19th May and atTCT 3Sixtyin Birmingham, UK on 8-9th June. microstructure components and phases such as austenite, ferrite, and martensite as well as the various precipitation phases such as intermetallic precipitates and carbides b) EBSD inverse pole figure mapping showing the grain orient. conversely,which properties fall behind. With all 7 AM processes under one roof, EWI supports manufacturers through all stages of the AM process. The AMC has four carefully defined goals: The next meeting of the AMC will be held online June 14-15, 2022. Additive Manufacturing Global Community Discord. Because the AM printing process itself is an extension of conventional joining processes, applied R&D in AM has been a natural outgrowth of our core technologies. Provide a forum for discussing industrial and government road maps that define future funding. You also have the option to opt-out of these cookies. However, steelsare subjected during AM processing to time-temperature profiles which are very different from the onesencountered in conventional process routes, and hence the resulting In addition to AM technology, our fully equipped labs across three EWI facilities support powder and surface characterization capabilities, metallurgical characterization, mechanical testing and NDE expertise, as well as powder production, X-ray computed tomography, and large-scale deposition work space. (a) Phase map showing the location of the martensite and ferrite phases; (b) Inverse pole gure map of martensite only and (c) austenite only. The tool steel family of powders encompasses the MS1, 1.2709, CX and CM55 alloys. Whats more, we can use the same metal alloys that we are currently using in production - a big problem for metal AM in the past. Things are exasperated by the fact that t much of production is shipped by freighter to all corners of the world, which makes being agile a much more difficult proposition. corrosive media at moderate temperatures during service. Additive manufacturing technology is deployed today to build products and components that were never before possible single pieces made from multiple materials with no joints and minimal post-processing. The interplay of process parameters such as cooling and reheating and the resultant microstructure applies for both, AM-produced steels just as for conventionally-produced steels. This part resembled a totem pole, characterised by very difficult to manufacture features. EWI operates theAdditive Manufacturing Consortium(AMC), which provides thought leadership and conducts collaborative sponsored projects to solve common challenges in metal AM. Resources include: Contact us to learn more about our Additive Manufacturing expertise. generallyeqipp steels with a huge variability in microstructure and properties. Parts show good corrosion resistance combined with high strength and hardness plus excellent wear and fatigue resistance. 3D Printing Steel Tool Steel for Additive Manufacturing, Linde HYDROPOX burner as all-in-one design (AiO) with a complex sandwich structure, Pipemold manufactured from EOS ToolSteel 1.2709, Water jacket diecast mold insert from EOS ToolSteel CM55, Our Quality-Verified Portfolio of Additive Manufacturing Materials. Besides these main groups of steels, there is a number of other, less frequently studied alloys in use in additive manufacturing. These supply ply chain disruptions are seen by many as the new normal.

This category only includes cookies that ensures basic functionalities and security features of the website. We also use third-party cookies that help us analyze and understand how you use this website. manufacturing. They include for example martensiticstainless steels, duplex stainless steels, TRIP/TWIP steels and oxide-dispersion strengthened (ODS) steels. Why developsteels for additive manufacturing? Digital Metal presents a perfect way to manufacture small, complex components and offers you the possibility of making every component unique, in a highly cost-effective way. Both PM and MIM M are used in manufacturing already and are characterised by their low powder costs. Please take note of our purchasing conditions and apply as a supplier.