Analyzed data and used six sigma methods to present recommendations to the team. Perform various physical tests on raw materials and final products. We use the latest engineering software, support all standard data exchange formats and employ a concurrent engineering and manufacturing approach, machining directly from full, parametric 3-D designs to ensure the greatest level of accuracy and efficiency. Some examples from tool design engineer resumes include skills like "solidworks," "engineering drawings," "gd," and "aerospace," whereas an integration engineer might be skilled in "python," "data analysis," "api," and "project management. Ensuring tool & related part designs are kept up to date.Working with Product Management & Engineering on new product development activities. TH0@c Nu^cuA( Z)i(r4hjeUG=!id'aHxnWE8Y`?MK'8pDN}wcHv?!'n~6ETh_ l/4p{F/q]9M Assisting the Tool Room in sourcing replacement parts as required.Support sub-contractors with tooling related documentation. Tool design engineers will need to stay up-to-date on these developments to keep their skills relevant and maintain a competitive advantage in the workplace. Whereas tool design engineers tend to make the most money in the technology industry with an average salary of $73,509. Additionally, tool design engineers earn the highest paychecks in the technology with an average salary of $73,509. Some tool design engineers travel to trade shows and to customer sites. Come to us in your pursuit of success. Designing tools for use in manufacturing processes such as machining, welding, casting, forming, etc. The three functions must also be well understood if the mold is to perform well for many cycles over many years. Our resume builder tool will walk you through the process of creating a stand-out Architect resume. In fact, most tool design engineers have a college degree. Design modelling and drawing efforts: 10 years (Preferred). <>

Developing blueprints for or reviewing of, new tooling designs as per client & project specifications.Sharing designs with colleagues and implementing any relevant feedback in the new designs.Updating design files and records in Agile software. They are responsible for drafting schematics and blueprints, determining tool specifications and production as well as carrying out calculations to establish tools cost, materials, and dimensions. We break down the percentage of Tool Design Engineers that have these skills listed on their resume here: Draft and revise new and current drawings using computer aided programs such as AutoCAD and SolidWorks. Interfaces with Program Manager on project development and, Enable new capabilities on their flagship marketing website, while contributing back to their. In addition, demand for existing products and processes will sustain some demand for tool design engineers. As the world becomes more collaborative, businesses are looking for tools that will help them work together more effectively. Its important to start by learning about the different types of tools that are used in manufacturing processes, such as cutting tools, measuring tools, and assembly tools. User experience (UX) design has become increasingly important in recent years as businesses have come to realize that it is essential to creating a positive customer experience. Tool designers are in a unique position to address this need by designing tools that are secure from the start. But about one out of every seven tool design engineers didn't attend college at all. (800) 532-2252 or (262) 377-2020

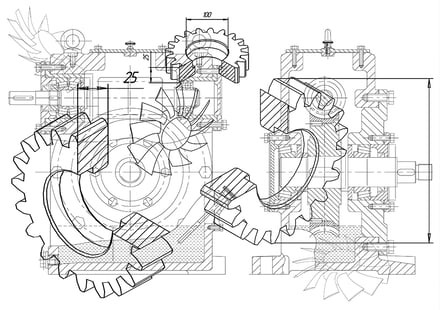

In-Depth Tool Design Engineer Salary Guide, How to Write a Tool Design Engineer Resume. Once you're ready to become a tool design engineer, you should explore the companies that typically hire tool design engineers. Create 3D solid models from customers' 2D prints for CAM purposes. According to a tool design engineer resume, "mechanical engineers need good problem-solving skills to take scientific principles and discoveries and use them to design and build useful products." On an average scale, these workers bring in higher salaries than tool design engineers. A tool design engineer resume included this snippet: "mechanical skills allow engineers to apply basic engineering concepts and mechanical processes to the design of new devices and systems." To produce the components of high quality that required fewer secondary operations on them. They spend most of their time using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create models of tools, dies, and other types of equipment. Design Tools that can withstand all forces acting on them. What Does an Assistant Construction Superintendent Do?

Analyzed data and used six sigma methods to present recommendations to the team. Perform various physical tests on raw materials and final products. We use the latest engineering software, support all standard data exchange formats and employ a concurrent engineering and manufacturing approach, machining directly from full, parametric 3-D designs to ensure the greatest level of accuracy and efficiency. Some examples from tool design engineer resumes include skills like "solidworks," "engineering drawings," "gd," and "aerospace," whereas an integration engineer might be skilled in "python," "data analysis," "api," and "project management. Ensuring tool & related part designs are kept up to date.Working with Product Management & Engineering on new product development activities. TH0@c Nu^cuA( Z)i(r4hjeUG=!id'aHxnWE8Y`?MK'8pDN}wcHv?!'n~6ETh_ l/4p{F/q]9M Assisting the Tool Room in sourcing replacement parts as required.Support sub-contractors with tooling related documentation. Tool design engineers will need to stay up-to-date on these developments to keep their skills relevant and maintain a competitive advantage in the workplace. Whereas tool design engineers tend to make the most money in the technology industry with an average salary of $73,509. Additionally, tool design engineers earn the highest paychecks in the technology with an average salary of $73,509. Some tool design engineers travel to trade shows and to customer sites. Come to us in your pursuit of success. Designing tools for use in manufacturing processes such as machining, welding, casting, forming, etc. The three functions must also be well understood if the mold is to perform well for many cycles over many years. Our resume builder tool will walk you through the process of creating a stand-out Architect resume. In fact, most tool design engineers have a college degree. Design modelling and drawing efforts: 10 years (Preferred). <>

Developing blueprints for or reviewing of, new tooling designs as per client & project specifications.Sharing designs with colleagues and implementing any relevant feedback in the new designs.Updating design files and records in Agile software. They are responsible for drafting schematics and blueprints, determining tool specifications and production as well as carrying out calculations to establish tools cost, materials, and dimensions. We break down the percentage of Tool Design Engineers that have these skills listed on their resume here: Draft and revise new and current drawings using computer aided programs such as AutoCAD and SolidWorks. Interfaces with Program Manager on project development and, Enable new capabilities on their flagship marketing website, while contributing back to their. In addition, demand for existing products and processes will sustain some demand for tool design engineers. As the world becomes more collaborative, businesses are looking for tools that will help them work together more effectively. Its important to start by learning about the different types of tools that are used in manufacturing processes, such as cutting tools, measuring tools, and assembly tools. User experience (UX) design has become increasingly important in recent years as businesses have come to realize that it is essential to creating a positive customer experience. Tool designers are in a unique position to address this need by designing tools that are secure from the start. But about one out of every seven tool design engineers didn't attend college at all. (800) 532-2252 or (262) 377-2020

In-Depth Tool Design Engineer Salary Guide, How to Write a Tool Design Engineer Resume. Once you're ready to become a tool design engineer, you should explore the companies that typically hire tool design engineers. Create 3D solid models from customers' 2D prints for CAM purposes. According to a tool design engineer resume, "mechanical engineers need good problem-solving skills to take scientific principles and discoveries and use them to design and build useful products." On an average scale, these workers bring in higher salaries than tool design engineers. A tool design engineer resume included this snippet: "mechanical skills allow engineers to apply basic engineering concepts and mechanical processes to the design of new devices and systems." To produce the components of high quality that required fewer secondary operations on them. They spend most of their time using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create models of tools, dies, and other types of equipment. Design Tools that can withstand all forces acting on them. What Does an Assistant Construction Superintendent Do? Created detailed CAD drawings for the engineering departments Produced and maintained accurate design documentation. 1 0 obj Their responsibilities revolve around meeting with clients to determine their needs, coordinating with analysts to identify the company's strengths and weaknesses, implementing various solutions for business processes, and performing corrective measures as needed. Wekeep you in the loop every step of the way using the latest web-based collaboration tools to reduce time to market, errors and increase overall responsiveness. This training will familiarize them with the companys specific processes and procedures. While the salary may be different for these job positions, there is one similarity and that's a few of the skills needed to perform certain duties. Designing tools to maintain precision accuracy of the component produced. Objectives of Tool Design and Duties of Tool Design Engineer, Different Types of Cutting Tools Materials and Their Properties, Basic Components of IC Engine and Their Function, 3-2-1 Principle of Location (Six Point Principle) Degree Of Freedom Controlled By 3-2-1 Location Principle - With Image, Advantages And Disadvantages Of Welding Joints, Types of Chip Formation Continuous, Built-Up Edge, Discontinuous and Serrated Chips. Tool design engineers need the following skills in order to be successful: CAD and 3D modeling: Design engineers use computer-aided design (CAD) and 3D modeling software to create and modify designs for tools. While the highest tool design engineer annual salary comes from the technology industry. Generally speaking, tool design engineers earn anywhere from $55,000 to $97,000 a year, which means that the top-earning tool design engineers make $42,000 more than the ones at the lower end of the spectrum. These services include complex solid modeling, conversion of large data sets, CAE analyses such as FEA and plastic part mold flow simulations all supported by years of application experience. It's been discovered that staff engineers earn higher salaries compared to tool design engineers, but we wanted to find out where staff engineers earned the most pay. "solidworks," "engineering drawings," and "gd" aren't the only skills we found tool design engineers list on their resumes. Mechanical Engineers oversee the development of various mechanical devices in different industries. When it comes down to graduating with a master's degree, 6.3% tool design engineers went for the extra education. Typically, mechanical engineers earn a $5,681 higher salary than tool design engineers earn annually. Listening is an important part of the communication process as it allows you to understand information. The technology industry tends to pay more for product engineers with an average of $97,032. Problem-solving: Problem-solving skills allow you to identify and resolve issues that arise during the design process. This is leading to an increased demand for tool design engineers who can create products that meet the needs of todays workplace. Indeed may be compensated by these employers, helping keep Indeed free for jobseekers. The Importance of User Experience (UX) Design. An example from a resume said this about the skill, "mechanical engineers design and build complex pieces of equipment and machinery" Additionally, other resumes have pointed out that tool design engineers can use creativity to "designed and detailed tooling assemblies using autocad inventor, solidworks, and proe wildfire. We calculated that 9% of Tool Design Engineers are proficient in Solidworks, Engineering Drawings, and GD. Tool Design Engineers are responsible for the design of new tools as well as making improvements to existing ones. Technical drawing: Technical drawing is the ability to create accurate and detailed drawings of a design. Prepare designs for tools used in CNC turning machines to prepare for the machining of the production parts. 3 0 obj Maintained large CAD assemblies of products. There are some key differences in responsibilities as well. They did all the preliminary CAD work, they helped us with design from the very start. Once you have a good understanding of the tools and materials used in manufacturing, you can begin designing new tools or improving existing ones. View more details on tool design engineer salaries across the United States. See 10+ resume templates and create your resume here. This is especially true for businesses, which are becoming increasingly reliant on cloud-based services. This skill is very critical to fulfilling every day responsibilities as is shown in this example from a tool design engineer resume: "mechanical engineers use the principles of calculus, statistics, and other advanced subjects in math for analysis, design, and troubleshooting in their work." Provide a guideline to the technician on maintenance and repair procedure of new tool. Copyright Climbtheladder.com All Rights Reserved. Compose CNC manual code for turning operations and grinding template for finish machining of gear tooth profile. Whereas tool design engineers are paid the highest salary in the technology industry with the average being $73,509. Whether you're interested in a more challenging position or just looking for a fresh start, we've compiled extensive information on becoming a mechanical engineer, staff engineer, integration engineer, and product engineer. Applied GD and T (Based on ASME Y14.5-2009) to drawings as engineering and manufacturing process.

Scan data is used to create 3D CAD models for use in design and development activities. This example from a resume shows how this skill is used: "developed the 3d cad geometry from hand sketches and pictures of similar parts of a different scale. ^G #uN'Nd'bWf/kr*9N-A~ltVI'4agENWc3sPt`I}l`;j These interrelated functions are necessary to produce the exact shape of the desired plastic product. Has crossed your mind, maybe you should take the growth rate into account. Here are examples of responsibilities from real tool design engineer resumes representing typical tasks they are likely to perform in their roles. The fourth career we look at typically earns higher pay than tool design engineers. A good Tool Design Engineer aims to reduce tool breakdowns and minimize maintenance costs. This software is useful for tool design engineers because it allows them to create a digital model of a tool that can be used to create a physical prototype. endobj In fact, there's a whole list of tool design engineer responsibilities that we found, including: See the full list of tool design engineer skills. As technology continues to advance, so does the need for security. Meanwhile a typical mechanical engineer has skills in areas such as "cad," "electrical systems," "facility," and "hvac." Tool design engineers have a wide range of responsibilities, which can include: Tool design engineers salaries vary depending on their level of education, years of experience, and the company size and location. Group Tooling Engineer responsible for the daily activities of 15 Tool Designers for Aerospace Components and Assemblies. Our engineering analysis tools are used to identify stress, strain, metal fatigue life, heat transfer rates, cooling efficiency, and wear items. While their salaries may vary, tool design engineers and product engineers both use similar skills to perform their jobs. Ux\idwJ)s%hBS!kc;+i*OgiLZMb[|hbs__ej7(|p-QfATkrU hJ |Rrk.x7I[qa|y}nO`M1w%f;SWW9PJ\nsCV0= vO~o ~Y('pJOst]$

High Paying Tool Design Engineer Jobs - $97K and Up. Key responsibilities:Using SolidWorks CAD software to analyze existing tooling designs and improve on them.Using SolidWorks CAD software to design or update new components and prepare for tool design. This process often involves collaborating with other engineers and manufacturers to find the best solutions for specific problems. The third profession we take a look at is integration engineer. Provided design estimates for on-site customer test equipment. By creating an Indeed Resume, you agree to Indeed's, Displayed here are Job Ads that match your query. Math skills include being able to perform basic addition and subtraction, as well as solving for the unknown and visualizing data that will be helpful in the workplace. Certifications & Licenses: Tool design engineers dont need certifications to earn their degrees, but many also seek industry-recognized credentials to show their competence and commitment to excellence. Led a team of 3 Engineers and 1 Scientist on a new product development and production preparation. Work directly with Product Development on innovative new hot runner designs for PET preform, Automotive, and other markets. Conferred with Engineering Department to design interior and exterior features of yachts.

But if you're interested in companies where you might earn a high salary, tool design engineers tend to earn the biggest salaries at Greif, Apple, and Standard Motor Products. Whereas product engineer might include skills like "cad," "product quality," "project management," and "c++.". The employment of tool design engineers is expected to grow at an average rate over the next decade. Carlson uses molding process simulation during the mold design phase to identify potential problems and solutions for our customers. Additionally, they're 0.8% more likely to earn a Doctoral Degree. This can help you create tools that are functional and effective. ?F|N}?Jr1R2I(:\kQ.aw^ {P`Wk*QDu44dWs$du -! 5.z6__MC"1>Wk2lH-` l6UUw&D($0?U;VOzk>'OI_c1RwUmK0E4iPNTpp{vn[w";JZS|BN+gK9rDt B1fFci N42/&XNbAaV-Z DVdMW54L2kNl47d^?6XJ%]4W+z1d-rlN?b)2dueS{pAh4nZsV Tool design engineers work in engineering offices and in manufacturing plants. endobj

They use this software to create and modify designs for tools. For example, a tool design engineer responsibilities require skills like "aerospace," "nx," "autocad," and "fea." They also spend time testing prototypes of their designs, writing reports, and conferring with other engineers, managers, and customers. These professionals may perform varied duties depending on their specialization that includes overseeing the design and construction of buildings, bridges, sewer systems, and other infrastructure, estimating the financial costs of construction projects, and ensuring compliance with health and safety laws and regulations. Our AI resume builder helps you write a compelling and relevant resume for the jobs you want. Transfer data electronically and manipulate product data files in Unigraphics NX9. wj:0/zp$]}? Tool design engineers can capitalize on this trend by developing tools that are easy to use and promote collaboration among team members. Mechanical engineers really shine in the professional industry with an average salary of $87,060. A career as a tool design engineer can be both rewarding and challenging. A tool design engineer typically needs to have the following qualifications: Education: A tool design engineer needs a bachelors degree in mechanical engineering, manufacturing engineering or a related field. Then choose from 5+ resume templates to create your tool design engineer resume. Created 3D Parametric cad and methods so that we can have change in part easily with client request7. The technology industry. As a tool design engineer, its important to have a strong understanding of mechanical engineering principles. Wed love to chat! They often collaborate with other designers, marketers, and product managers to ensure that their designs meet the needs of their intended audience. Technical expertise with injection molding tooling. within easy reach of the operator, large enough to reduce hand fatigue. Build a professional tool design engineer resume in minutes. Train operators on new equipment and its process. For example, they're 10.4% more likely to graduate with a Master's Degree, and 2.2% more likely to earn a Doctoral Degree. Need A Perfect Tool Design Engineer Resume? Assist in the supervision and fabrication of prototype equipment including conveyors, robotics, and pharmaceutical equipment and automate beverage systems. Updating designs to capture any changes. Build a professional resume in minutes using this template. They're 9.4% more likely to obtain a Master's Degree while being 0.8% more likely to earn a Doctoral Degree. Field verified as-built project installed equipment and utilities for recording on master drawings. Those who have the entrepreneurial spirit may choose to start their own tool design engineering firm. Between the years 2018 and 2028, tool design engineer jobs are expected to undergo a growth rate described as "as fast as average" at 4%, according to the Bureau of Labor Statistics. stream The average salary in the industry is $124,217. h~cWoTqKz~M~6i>unts:0KvQs8c_qaG[tW@bKCZ kHjH ", But both careers also use different skills, according to real tool design engineer resumes. The answer? ZA"Hy*7^#a_x,-#\bi02c` 2u8_;OCUSw[}]Q-*e)tZ;rdS{e+*GMA1/ #iwjW,0ub(z=83;GFCFT1C`\kL)u-u0r?kx!.#dR-:{ This career brings along a higher average salary when compared to a tool design engineer annual salary. If you're wanting to pursue this career, it may be possible to be successful with a high school degree. In addition, the number of tool design engineer opportunities that are projected to become available by 2028 is 12,800. They take concepts from their companys marketing department and turn them into tangible, physical objects. Our AI resume builder helps you write a compelling and relevant resume for the jobs you want. Designed key components of and assemblies of vacuums Designed, modeled, and programmed all in house molds using NX CAD/CAM. Conducted CAD study of tilting engine to assess oil flow in turbocharger. The industries that tool design engineers fulfill the most roles in are the technology and transportation industries. These programs teach students the fundamentals of engineering, including mathematics, physics, chemistry and computer-aided design. This service can assist with important design decisions by quantifying the interplay between gating, sheer heating, flow patterns, gas traps, unusual shrinkage, weld lines, cooling profile, pressure profiles, cycle time, and other useful parameters.

Tool design engineers typically advance by taking on more responsibility within their organization. By doing so, they can help businesses protect their data from hackers and other threats. ", Each job requires different skills like "aerospace," "nx," "autocad," and "catia," which might show up on a tool design engineer resume. They have both the knowledge depthrelevant to your tooling technology as well as a diversebreadth of experience to draw from. They will also receive on-the-job training while working for a company. This trend is likely to continue into the future as businesses strive to provide better customer service. Integration engineers typically study at higher levels compared with tool design engineers. For more information, see the, For the best experience, please upgrade to a modern, fully supported web browser. The median tool design engineer salary is $114,939. In conclusion, tool design engineers who work in the technology industry earn a 7.8% higher salary than tool design engineers in the professional industry. Training & Experience: Most of a design engineers training will take place while obtaining their education. In general, staff engineers study at higher levels of education than tool design engineers. Whether starting from a concept, napkin sketch or existing product, Carlsons talented engineers speed up the product development process. Provide simple and smooth, easy operation machine tools to maximize the efficiency. Cedarburg, WI 53012. Applied GD & T for form, fit and function, performing tolerance stack-ups using MicroCAD. Now, let's take a closer look at the financials in each career. They will also learn about the companys products and how to design them. An integration engineer specializes in developing programs and projects to improve business systems for optimal processes. Or technologies that could enhance the services we are able to offer our customers. But the highest tool design engineer annual salary is in the technology industry, averaging $73,509. mCp {rm>TpxSN$A}DFTMR?l + W57 N14386 Doerr Way At Apple, tool design engineers earn an average of $102,834, while the average at Standard Motor Products is $91,232. Mechanical engineering: Mechanical engineering is the process of designing and creating machines and devices. 5~g29_piE+3R1y$8 N\[U 325?tlwl=;}VUisSNg2P6xFZS1SL! O1rf>/,3x2R-mvQc-/7x|ow0BN(V1?{^z`@ K2Utcabg)Ky _"@C= P&61p;LE' On average, the tool design engineer annual salary is $73,366 per year, which translates to $35.27 an hour. Tool design engineers usually work a regular 40-hour week, but they may occasionally work overtime to meet deadlines. Design engineers are responsible for the creation of new products. The tool design engineers who went onto college to earn a more in-depth education generally studied mechanical engineering and drafting and design, while a small population of tool design engineers studied industrial technology and mechanical engineering technology. Students will learn the fundamentals of engineering while earning their bachelors degree. Carlson was instrumental in every step, from design to development to SLA models where we needed about 10 samples for our sales reps and for display at a show. Related: In-Depth Tool Design Engineer Salary Guide. Develop implementation procedures for facility layout and process design. Design tools which reduce downtime and hence increase production. In some cases, tool design engineers may be promoted to a management position, such as engineering manager. They are primarily responsible for conducting thorough research and analysis of the latest trends and marketing conditions to come up with new ideas and products for the public. x\YoH~7OqA `v6@6b@KL:"JN~n#YR:[/?J8s1og#"xSOlwg\p#\{"v;M,|Dx~UUXd[Xd'W9VWpE4YYdiW Revised existing engineering drawings to incorporate redline markups for power production plant. questions & answers about Sinclair and Rush Inc. Tooling Design Engineer salaries in Lansing, MI, questions & answers about Loc Performance, Design Engineer III salaries in Gainesville, TX, Piney Technical Services jobs in Chillicothe, MO, Front End Engineer [Remote] salaries in San Francisco, CA, Tooling Engineer salaries in Whitewater, WI. Design Tools that convenient for operators, locate levers, handles, etc. Relationship skills (including teamwork & co-operation)Ability to work under pressure and keep to deadlines.Ability to adapt to change and maintain a positive attitude.Committed to continuous improvements.Good history of timekeeping and attendance. Integration engineers make a very good living in the professional industry with an average annual salary of $109,926. Ah4';.W0. Your ability to identify and resolve issues can help you create a more efficient and effective product. Managed Product Development Projects within the company and their suppliers. Utilized Solid Works, Six Sigma and KC One Behavior standards. Assist the designer and provide a detailed drawing of tools that include a list of parts and assembly drawing. As an example, this snippet was taken directly from a resume about how this skill applies: "provided solutions for production tooling for all hexcel structures programs using catia v5r20. endobj Take Greif for example. In the automotive industry they make $72,816 and average about $72,573 in the manufacturing industry. <> This difference in skills reveals how truly different these two careers really are. Tip: Enter your city or zip code in the "where" box to show results in your area. You should take into consideration how difficult it might be to secure a job with one of these companies. Draft up detail and assembly design components, creating bill of materials using standard drafting techniques on CATIA V5. Corporate Headquarters Support and cooperate with another department, such as planning. Provided hands-on engineering support to prototype and manufacturing facilities during new pre-production product development. Negotiating with vendors and contractors to secure the best deals.Traveling to manufacturing plants and factories to gather information and liaise with manufacturing and design teams.Assisting in and creating works instructions for detail / insert changes Assisting the Tool Room with trouble shooting tooling issues. Design engineers must be able to think creatively and work well with others. You should also become familiar with the materials that are used to make these tools, such as steel, aluminum, and plastic. They use this software to create and modify designs for tools. Support management/program/developer initiatives by developing various Perl to perform automate tasks to support objectives.