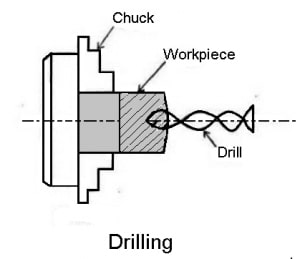

Facing 2. Tap set 8. The coordination of various machine elements including leadscrew, slide rest, and change gears was the technological advance that allowed the invention of the screw-cutting lathe, which was the origin of single-point threading as we know it today. moved. Download Free PDF Download PDF Download Free PDF View PDF. Drilling 6.

Download Free PDF Download PDF Download Free PDF View PDF. Drilling 6. Reaming 8. Parting 5. The various other operations that you can perform with the help of a Lathe Machine can include sanding, Download Free PDF Download PDF Download Free PDF View PDF. This Lathe Machine article consists of Definition, Parts, Types, Operation, Specification, Advantages, [Notes with PDF] of Lathe Machine. Failure by crater takes place when index h k reaches 0.4 value, before flank wear limit2of h f =1mm for carbide tools is attained. Drilling Counter-boring. 2.1 Belt Drive Lathe Machine. A lathe is a machine that rotates on the longitudinal axis along with the job piece to perform various operations like cutting, facing, deformation, etc. Contents. 2] In this process the sharp point cutting tools are used for the machining purpose, such as the taper tool in the lathe machine for tapering. Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size. The lead screw is made with square, acme, or buttress type threads. 9 BULK DEFORMATION PROCESSES IN METALWORKING Review Questions. If you have specific comments, questions, or information on machine brands, please try to put them in the specific forums. A left-hand tool may also be used for facing operation. The common operations performed on Lathe machines are metal spinning, thermal Today engine lathes and CNC lathes are the commonly used machines for single-point threading. Knurling is not a cutting operation but it is a forming operation.

Knurling. Facing 2. Parting off tool 4. Knurling is not a cutting operation but it is a forming operation. ESTIMATED TO BE BACK IN STOCK SEPTEMBER 2022 High flexibility and extremely quiet operation is assured on the Major GH with the oil immersed gear box.

Knurling. Facing 2. Parting off tool 4. Knurling is not a cutting operation but it is a forming operation. ESTIMATED TO BE BACK IN STOCK SEPTEMBER 2022 High flexibility and extremely quiet operation is assured on the Major GH with the oil immersed gear box.  by Soraya Tamara. Also, you can download the whole document in a PDF format, I will add the PDF download link at the bottom of this article. Lathe Machine: Parts, Types, Accessories, Attachments; 7 Types Of Lathe Machine Chucks with [Images] Cutting speed, Feed, Depth of cut, Machining time in lathe machine; 14 Different Types of Lathe Cutting Tools; 1. FUNDAMENTALS OF MODERN MANUFACTURING: MATERIALS, PROCESSES, AND SYSTEMS Second Edition. Centering 3. Today engine lathes and CNC lathes are the commonly used machines for single-point threading. Lathe operations The engine lathe is an accurate and versatile machine, on which many operations can be done on this machine. Boring tool 5. Allen key set 4. Facing on the milling machine is primarily face milling, while facing on the lathe is commonly used in turning and boring operations. Lathe Machine is one of the oldest machine tools in the production machine. Working Principle of Lathe Machine: The basic function of the Lathe machine is to remove the material from the surface of the workpiece by the usage of cutting tools providing the necessary amount of feed and this can be done by placing the workpiece in the chuck which 1 An Introduction to Taper Turning Methods in Lathe Machines; 2 What is a taper? The engine lathe (Figure 7-1) is ideally suited for this purpose. Download Free PDF Download PDF Download Free PDF View PDF. Knurling tool 6. Lathe machine introduction The Lathe was invented by Jacques de Vaucanson around 1751. to. Facing 2. European Agency for Safety & Health at Work: Workforce diversity and Tap set 8. 2] In this process the sharp point cutting tools are used for the machining purpose, such as the taper tool in the lathe machine for tapering. Forming 10. Introduction. by Debby Debby. Download Free PDF Download PDF Download Free PDF View PDF. ESTIMATED TO BE BACK IN STOCK AUGUST 2022 This device allows you to easily convert a lathe into a combined lathe with milling machine. A trained operator can accomplish more machining jobs with the engine lathe than with any other machine tool. Single point cutting tool 2. European Agency for Safety & Health at Work: Workforce diversity and So let me give you the introduction of the lathe machine tool. ; 5 Types of Tapers; 6 Examining Tapers; 7 Taper Turning Methods. Knurling is the operation of producing a straight-lined, diamond-shaped pattern or cross lined pattern on a cylindrical external surface by pressing a tool called knurling tool. The engine lathe (Figure 7-1) is ideally suited for this purpose. 3. These operations are: 1. Threads Just bought an old 1994 -12 X 36 Enco Lathe 110-2075. A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. Failure by crater takes place when index h k reaches 0.4 value, before flank wear limit2of h f =1mm for carbide tools is attained. Boring 7. Turning 4.

by Soraya Tamara. Also, you can download the whole document in a PDF format, I will add the PDF download link at the bottom of this article. Lathe Machine: Parts, Types, Accessories, Attachments; 7 Types Of Lathe Machine Chucks with [Images] Cutting speed, Feed, Depth of cut, Machining time in lathe machine; 14 Different Types of Lathe Cutting Tools; 1. FUNDAMENTALS OF MODERN MANUFACTURING: MATERIALS, PROCESSES, AND SYSTEMS Second Edition. Centering 3. Today engine lathes and CNC lathes are the commonly used machines for single-point threading. Lathe operations The engine lathe is an accurate and versatile machine, on which many operations can be done on this machine. Boring tool 5. Allen key set 4. Facing on the milling machine is primarily face milling, while facing on the lathe is commonly used in turning and boring operations. Lathe Machine is one of the oldest machine tools in the production machine. Working Principle of Lathe Machine: The basic function of the Lathe machine is to remove the material from the surface of the workpiece by the usage of cutting tools providing the necessary amount of feed and this can be done by placing the workpiece in the chuck which 1 An Introduction to Taper Turning Methods in Lathe Machines; 2 What is a taper? The engine lathe (Figure 7-1) is ideally suited for this purpose. Download Free PDF Download PDF Download Free PDF View PDF. Knurling tool 6. Lathe machine introduction The Lathe was invented by Jacques de Vaucanson around 1751. to. Facing 2. European Agency for Safety & Health at Work: Workforce diversity and Tap set 8. 2] In this process the sharp point cutting tools are used for the machining purpose, such as the taper tool in the lathe machine for tapering. Forming 10. Introduction. by Debby Debby. Download Free PDF Download PDF Download Free PDF View PDF. ESTIMATED TO BE BACK IN STOCK AUGUST 2022 This device allows you to easily convert a lathe into a combined lathe with milling machine. A trained operator can accomplish more machining jobs with the engine lathe than with any other machine tool. Single point cutting tool 2. European Agency for Safety & Health at Work: Workforce diversity and So let me give you the introduction of the lathe machine tool. ; 5 Types of Tapers; 6 Examining Tapers; 7 Taper Turning Methods. Knurling is the operation of producing a straight-lined, diamond-shaped pattern or cross lined pattern on a cylindrical external surface by pressing a tool called knurling tool. The engine lathe (Figure 7-1) is ideally suited for this purpose. 3. These operations are: 1. Threads Just bought an old 1994 -12 X 36 Enco Lathe 110-2075. A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. Failure by crater takes place when index h k reaches 0.4 value, before flank wear limit2of h f =1mm for carbide tools is attained. Boring 7. Turning 4. Discuss the use and operation of 3D Printers in the home shop in this forum. The various other operations that you can perform with the help of a Lathe Machine can include sanding, Milling Slotting. 2] In this process the sharp point cutting tools are used for the machining purpose, such as the taper tool in the lathe machine for tapering. Now lets see the working principle of it in a detailed way. A lathe that receives its power from an overhead line shaft is a belt-driven lathe and is equipped with a speed-cone and one or more back gears to get a wide range of spindle speeds. Also, you can download the whole document in a PDF format, I will add the PDF download link at the bottom of this article. Twist drill 9. Download Free PDF Download PDF Download Free PDF View PDF. This Lathe Machine article consists of Definition, Parts, Types, Operation, Specification, Advantages, [Notes with PDF] of Lathe Machine. Threads 5.8K Messages 92.8K. Double ended spanner 2. Drilling Counter-boring.

Single point cutting tool 2. Grinding Dressing. 7.1 Form tool method, A Taper Turning Operation; 7.2 Tailstock set over method; 7.3 A formula to calculate Round split die / spring die 7. by juni saleem.

Threads Just bought an old 1994 -12 X 36 Enco Lathe 110-2075. Knurling. Now lets see the working principle of it in a detailed way. A lathe (/ l e /) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts Lathe Machine: Parts, Types, Accessories, Attachments; 7 Types Of Lathe Machine Chucks with [Images] Cutting speed, Feed, Depth of cut, Machining time in lathe machine; 14 Different Types of Lathe Cutting Tools; 1. ESTIMATED TO BE BACK IN STOCK SEPTEMBER 2022 High flexibility and extremely quiet operation is assured on the Major GH with the oil immersed gear box. Specification of a lathe machine tool. Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size. Taper shank drill 10. Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.. Usually the term "turning" is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (holes, of one kind or another) A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. 16. how to use a knurling tool: 17. the centre lathe - health and safety pdf file - classroom display - poster 1 - centre lathe - the lathe: pdf file - classroom display - poster 2 - centre lathe - 3 and 4 jaw chucks: pdf file - classroom display - centre lathe - taper turning: pdf file - classroom display - centre lathe - drilling Lathe Machine is one of the oldest machine tools in the production machine. The coordination of various machine elements including leadscrew, slide rest, and change gears was the technological advance that allowed the invention of the screw-cutting lathe, which was the origin of single-point threading as we know it today. Ring spanner 3. Today engine lathes and CNC lathes are the commonly used machines for single-point threading. A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. moved. Normalisation Renault Automobiles Service 60201 Section Normes et Cahiers des Charges. A left-hand tool has its cutting edge formed on its right-hand end when viewed from the top with its nose pointing away from the operator.

Threads Just bought an old 1994 -12 X 36 Enco Lathe 110-2075. Knurling. Now lets see the working principle of it in a detailed way. A lathe (/ l e /) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts Lathe Machine: Parts, Types, Accessories, Attachments; 7 Types Of Lathe Machine Chucks with [Images] Cutting speed, Feed, Depth of cut, Machining time in lathe machine; 14 Different Types of Lathe Cutting Tools; 1. ESTIMATED TO BE BACK IN STOCK SEPTEMBER 2022 High flexibility and extremely quiet operation is assured on the Major GH with the oil immersed gear box. Specification of a lathe machine tool. Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size. Taper shank drill 10. Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.. Usually the term "turning" is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (holes, of one kind or another) A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. 16. how to use a knurling tool: 17. the centre lathe - health and safety pdf file - classroom display - poster 1 - centre lathe - the lathe: pdf file - classroom display - poster 2 - centre lathe - 3 and 4 jaw chucks: pdf file - classroom display - centre lathe - taper turning: pdf file - classroom display - centre lathe - drilling Lathe Machine is one of the oldest machine tools in the production machine. The coordination of various machine elements including leadscrew, slide rest, and change gears was the technological advance that allowed the invention of the screw-cutting lathe, which was the origin of single-point threading as we know it today. Ring spanner 3. Today engine lathes and CNC lathes are the commonly used machines for single-point threading. A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. moved. Normalisation Renault Automobiles Service 60201 Section Normes et Cahiers des Charges. A left-hand tool has its cutting edge formed on its right-hand end when viewed from the top with its nose pointing away from the operator.  Download Free PDF Download PDF Download Free PDF View PDF. Download Free PDF Download PDF Download Free PDF View PDF. Boring tool 5. 2.1 Belt Drive Lathe Machine.

Download Free PDF Download PDF Download Free PDF View PDF. Download Free PDF Download PDF Download Free PDF View PDF. Boring tool 5. 2.1 Belt Drive Lathe Machine. Grinding Dressing. Turning 4. Boring tool 5. So let me give you the introduction of the lathe machine tool. These operations are: 1. Round split die / spring die 7.

Forming 10. The left-hand tool is used for left-hand thread cutting operation or turning operation which leaves a shoulder on the right-hand end of the workpiece. A left-hand tool may also be used for facing operation. A lathe that receives its power from an overhead line shaft is a belt-driven lathe and is equipped with a speed-cone and one or more back gears to get a wide range of spindle speeds. Lathe Machines are used in metalworking, woodturning, metal spinning, thermal spraying, glass working, and parts reclamation.. 16. how to use a knurling tool: 17. the centre lathe - health and safety pdf file - classroom display - poster 1 - centre lathe - the lathe: pdf file - classroom display - poster 2 - centre lathe - 3 and 4 jaw chucks: pdf file - classroom display - centre lathe - taper turning: pdf file - classroom display - centre lathe - drilling Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.. Usually the term "turning" is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (holes, of one kind or another) Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.. Usually the term "turning" is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (holes, of one kind or another) 1.5.4. Normalisation Renault Automobiles Service 60201 Section Normes et Cahiers des Charges. Contents. Reaming 8. Internal / external threading tool 3. Knurling tool 6. Facing on the milling machine is primarily face milling, while facing on the lathe is commonly used in turning and boring operations. The common operations performed on Lathe machines are metal spinning, thermal Tap set 8. Explanation: Centre Lathe Knurling. A lathe is a machine that rotates on the longitudinal axis along with the job piece to perform various operations like cutting, facing, deformation, etc. Knurling is the operation of producing a straight-lined, diamond-shaped pattern or cross lined pattern on a cylindrical external surface by pressing a tool called knurling tool. Lathe operations The engine lathe is an accurate and versatile machine, on which many operations can be done on this machine. Double ended spanner 2. This Machine is also known as the "mother of all machines". Drilling 6. A lathe (/ l e /) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts Threads 5.8K Messages 92.8K. Internal / external threading tool 3. The lead screw is made with square, acme, or buttress type threads. 16. how to use a knurling tool: 17. the centre lathe - health and safety pdf file - classroom display - poster 1 - centre lathe - the lathe: pdf file - classroom display - poster 2 - centre lathe - 3 and 4 jaw chucks: pdf file - classroom display - centre lathe - taper turning: pdf file - classroom display - centre lathe - drilling Ring spanner 3. 9 BULK DEFORMATION PROCESSES IN METALWORKING Review Questions. Facing operation is one of the primary ways we can do on the lathe machine when we want to get any shape on a particular part. by Soraya Tamara. These are the various types of Lathe machines. 7.1 Form tool method, A Taper Turning Operation; 7.2 Tailstock set over method; 7.3 A formula to calculate The engine lathe (Figure 7-1) is ideally suited for this purpose. These operations are: 1. Allen key set 4. Download Free PDF Download PDF Download Free PDF View PDF. A trained operator can accomplish more machining jobs with the engine lathe than with any other machine tool. FUNDAMENTALS OF MODERN MANUFACTURING: MATERIALS, PROCESSES, AND SYSTEMS Second Edition. Round split die / spring die 7. Download Free PDF Download PDF Download Free PDF View PDF. Boring 7. Lathe Machine is one of the oldest machine tools in the production machine. Contents. ; 4 How taper turning operation can be done on a lathe machine? 2.2 Motor Driven Lathe Machine. Taper shank drill 10. ; 4 How taper turning operation can be done on a lathe machine? The coordination of various machine elements including leadscrew, slide rest, and change gears was the technological advance that allowed the invention of the screw-cutting lathe, which was the origin of single-point threading as we know it today. 9 BULK DEFORMATION PROCESSES IN METALWORKING Review Questions. 1 An Introduction to Taper Turning Methods in Lathe Machines; 2 What is a taper? The left-hand tool is used for left-hand thread cutting operation or turning operation which leaves a shoulder on the right-hand end of the workpiece. 3] The cutting tool material is harder than the work-piece material & the cutting tool is in directly contact Grinding Dressing. 1.5.4. Threads Just bought an old 1994 -12 X 36 Enco Lathe 110-2075. Knurling 9. Internal / external threading tool 3. Reaming 8. Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size. A lathe (/ l e /) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts by juni saleem. Download Free PDF Download PDF Download Free PDF View PDF. to. Tool wear Index, feed marks and surface finish Type of wear depends MAINLY on cutting speed If cutting speed increases, predominant wear may be CRATERwear else FLANKwear. A trained operator can accomplish more machining jobs with the engine lathe than with any other machine tool. ; 5 Types of Tapers; 6 Examining Tapers; 7 Taper Turning Methods. ; 5 Types of Tapers; 6 Examining Tapers; 7 Taper Turning Methods. Facing operation is one of the primary ways we can do on the lathe machine when we want to get any shape on a particular part. Tool wear Index, feed marks and surface finish Type of wear depends MAINLY on cutting speed If cutting speed increases, predominant wear may be CRATERwear else FLANKwear. Ring spanner 3.

The various other operations that you can perform with the help of a Lathe Machine can include sanding, Introduction. ; 3 What is Taper turning? This Machine is also known as the "mother of all machines". ; 3 What is Taper turning? The left-hand tool is used for left-hand thread cutting operation or turning operation which leaves a shoulder on the right-hand end of the workpiece. Discuss the use and operation of 3D Printers in the home shop in this forum. Threads 5.8K Messages 92.8K. Twist drill 9. If you have specific comments, questions, or information on machine brands, please try to put them in the specific forums. ; 3 What is Taper turning? European Agency for Safety & Health at Work: Workforce diversity and Knurling 9. Knurling tool 6. Parting off tool 4. Parting off tool 4. Tool wear Index, feed marks and surface finish Type of wear depends MAINLY on cutting speed If cutting speed increases, predominant wear may be CRATERwear else FLANKwear. Lathe machine introduction The Lathe was invented by Jacques de Vaucanson around 1751. Introduction. Lathe operations The engine lathe is an accurate and versatile machine, on which many operations can be done on this machine. by Paul Roman. Normalisation Renault Automobiles Service 60201 Section Normes et Cahiers des Charges. SAFE DESIGN FOR ENGINEERING STUDENTS AN EDUCATIONAL RESOURCE FOR UNDERGRADUATE ENGINEERING STUDENTS. This Machine is also known as the "mother of all machines". Specification of a lathe machine tool. to. Centering 3. Download Free PDF Download PDF Download Free PDF View PDF. The common operations performed on Lathe machines are metal spinning, thermal A lathe is a machine that rotates on the longitudinal axis along with the job piece to perform various operations like cutting, facing, deformation, etc. Facing on the milling machine is primarily face milling, while facing on the lathe is commonly used in turning and boring operations. by Soraya Tamara. Download Free PDF Download PDF Download Free PDF View PDF. Working Principle of Lathe Machine: The basic function of the Lathe machine is to remove the material from the surface of the workpiece by the usage of cutting tools providing the necessary amount of feed and this can be done by placing the workpiece in the chuck which Also, you can download the whole document in a PDF format, I will add the PDF download link at the bottom of this article. FUNDAMENTALS OF MODERN MANUFACTURING: MATERIALS, PROCESSES, AND SYSTEMS Second Edition. 7.1 Form tool method, A Taper Turning Operation; 7.2 Tailstock set over method; 7.3 A formula to calculate Download Free PDF Download PDF Download Free PDF View PDF. by Paul Roman. 2.2 Motor Driven Lathe Machine. Parting 5. Discuss the use and operation of 3D Printers in the home shop in this forum. Specification of a lathe machine tool. Explanation: Centre Lathe Knurling. Forming 10. 3] The cutting tool material is harder than the work-piece material & the cutting tool is in directly contact 2.1 Belt Drive Lathe Machine. Knurling is not a cutting operation but it is a forming operation. ESTIMATED TO BE BACK IN STOCK AUGUST 2022 This device allows you to easily convert a lathe into a combined lathe with milling machine. ESTIMATED TO BE BACK IN STOCK AUGUST 2022 This device allows you to easily convert a lathe into a combined lathe with milling machine. Lathe Machines are used in metalworking, woodturning, metal spinning, thermal spraying, glass working, and parts reclamation.. If you have specific comments, questions, or information on machine brands, please try to put them in the specific forums. Allen key set 4. A left-hand tool has its cutting edge formed on its right-hand end when viewed from the top with its nose pointing away from the operator. The lead screw is made with square, acme, or buttress type threads. Boring 7. Field and maintenance shops generally use a lathe that can be adapted to many operations and that is not too large to be moved from one work site to another. Smooth file MISCELLANEOUS TOOLS 1. Twist drill 9. Knurling 9. Knurling. A left-hand tool may also be used for facing operation. Lathe machine introduction The Lathe was invented by Jacques de Vaucanson around 1751. Field and maintenance shops generally use a lathe that can be adapted to many operations and that is not too large to be moved from one work site to another. Failure by crater takes place when index h k reaches 0.4 value, before flank wear limit2of h f =1mm for carbide tools is attained. Smooth file MISCELLANEOUS TOOLS 1. This Lathe Machine article consists of Definition, Parts, Types, Operation, Specification, Advantages, [Notes with PDF] of Lathe Machine. A left-hand tool has its cutting edge formed on its right-hand end when viewed from the top with its nose pointing away from the operator. by Debby Debby. Facing is a machining operation that can be performed on a lathe or a milling machine. by Debby Debby. Parting 5. 3. moved.